Every home needs a neutral temperature, keeping it neutral even at peculiar and chilling temperatures. This article lays out everything you need to know about thermal Insulation, how to make their house fully insulated, the benefits of the same, and other questions on the same subject.

What Does Thermal Insulation Mean?

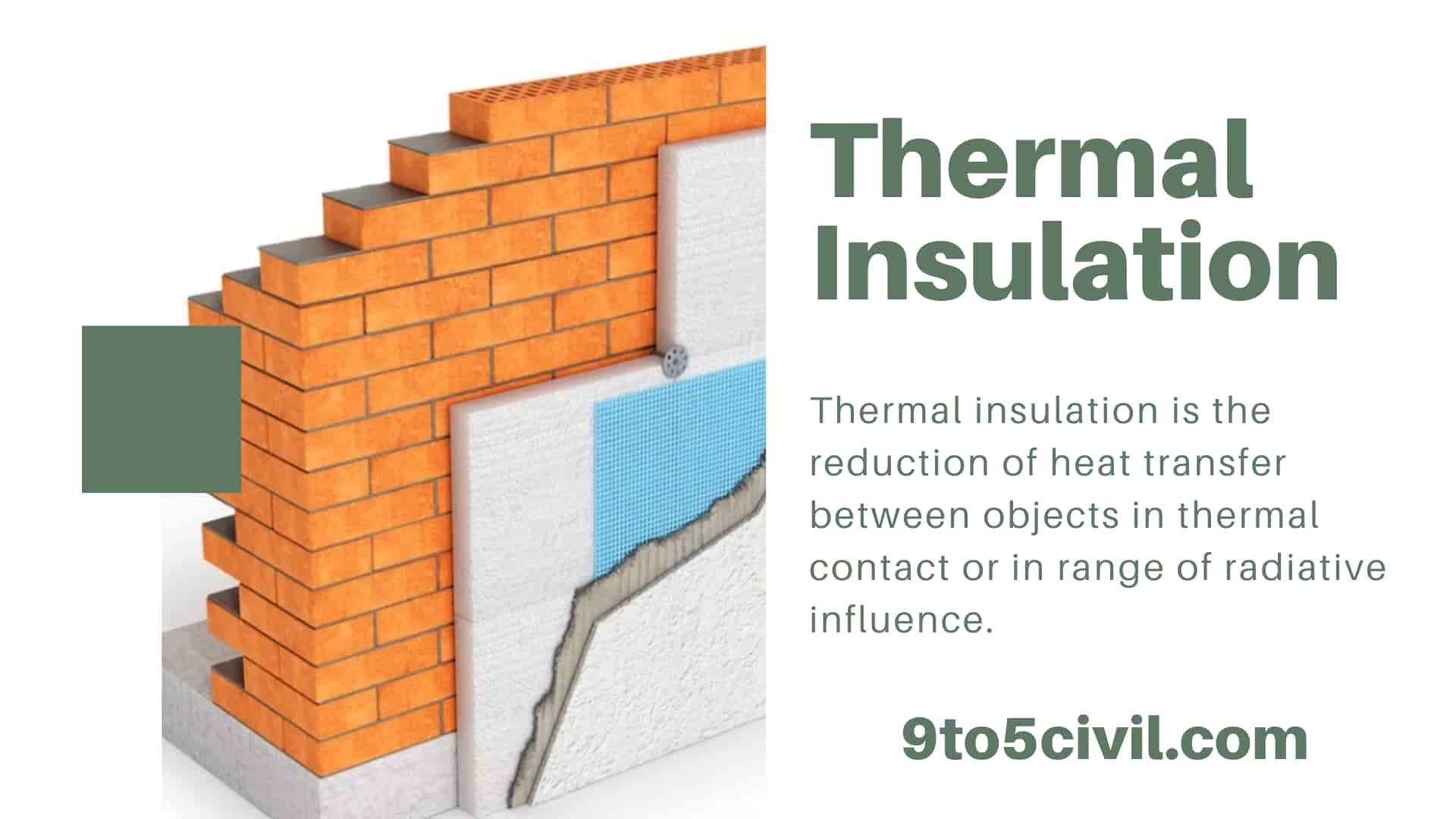

The thermal insulation process limits the amount of heat transfer energy in any building in thermal exposure between objects in a range of radioactive effects. The installation of such thermal Insulation calls for unique engineered methods and processes, along with appropriate object shapes and materials.

These peculiar materials, popularly regarded as insulators/thermal insulators, are put up in commercial structures to improve energy consumption within the area, thereby neutralizing the building’s hot and excellent systems.

Not only this, but industrial systems also take turns to thermal Insulation for the mere reason of bringing under control any heat gain or loss on process piping and equipment, steam and condensate distribution systems, boilers, and others.

To thermally insulate, there should be a constraint on the amount of heat that is being transferred from one place to the other. Thus, the material used as Insulation should necessarily thwart heat gushing across the adjacent surfaces of contacting materials by using any heat transmission step.

Although thermal Insulation improves energy efficiency and transmission, it has a flip side as well, which isn’t as pleasant and likable as it seems. In petrochemical industries, the Thermal Insulation of pipes causes the steel and other equipment to corrode massively.

This glaring problem causes plant failure and various other accidents in the fullness of time. Failing to control and dig deep under thermal Insulation could lead to aggravated effects, eventually shutting the plan down.

Further, the two types of corrosion that are caused by corrosion due to thermal Insulation are oxidation of carbon steel and chloride stress-corrosion, which needs to be dealt with immediately. This corrosion could be foiled by clamping down any moisture build-up or fending off chloride ions presence. Installation of jackets and periodic painting could keep a tight rein on any rusting attacks.

What Are the Thermal Insulation Materials?

Before setting about the task of laying out thermal insulation materials and installing them, there are a few considerations that you need to make. These are regarding to-be-chosen material’ R-value, price, acoustic values, and whether or not it is environment friendly. Go through the following list of common and widely chosen materials and what they bring along with them.

1. Mineral Wool Thermal Insulation:

This material is capable of covering a handful of insulations. Either glass wool or rock wool could be regarded as mineral wool, where the former is fiberglass manufactured using recycled glass while the latter is made from basalt.

One can purchase mineral wool either as a loose material or in batts. Furthermore, most of these don’t have any additives to make them fire-proof, thus making it an unlikeable option especially in situations of extreme heat.

As for its R-value, it could be anywhere from R-2.8 to R-3.5.

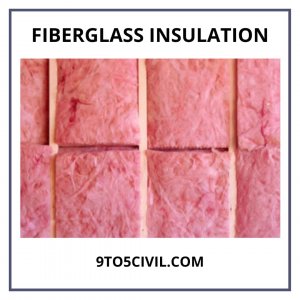

2. Fibreglass Thermal Insulation:

Fiberglass is widely acknowledged as one of the best materials. This could be accredited to it’s value. In addition to the previous statement, the installation cost for such material is relatively lesser than other types of materials offering less/equal R-value.

When set against materials like cellulose or spray foam insulation systems, these incontrovertibly stand much lower in respect to it’s cost. One might think what makes them this cost-effective, this could be owed to its effectively weaving fine strands of glass to convert into insulation material.

Talking about its advantages, these have the latency to keep heat transfer in check. Professionals or even the homeowners must necessarily keep in mind to keep safety equipment handy, as the glass power and tiny bits of glass are formed, which puts eyes, lungs, and skin in jeopardy. As far as its R-value is concerned, you are getting an R-value of R-2.9 to R-3.8 per inch.

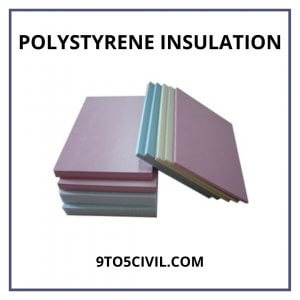

3. Polystyrene Thermal Insulation:

This material is a water-resistant thermoplastic foam that successfully thwarts outside noises and temperature. This material is of two types: Expanded (EPS) and extended (XEPS), alternatively known as styrofoam. The latter one is costlier and understandably so, for it boasts a high R-value of R-5.5.

The former does not seem to hold back, for it has a uniquely smooth surface that no other material could have. One can find the materials both in residential areas and commercial settings. The only downside of polystyrene would be that it is rigid and not fluffy. Nonetheless, these are an ideal choice for wall insulation.

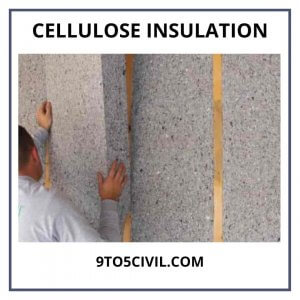

4. Cellulose Thermal Insulation:

This next material is considered to be eco-friendly. As for the composition, one is bound to be left astonished that it is composed of 75-85% recycled paper fiber. Concerning the other 15%, it’s a fire retardant like boric acid or ammonium sulfate.

The material doesn’t have oxygen, making it flammable, or there is little to no fear of fire eruption. This also stands because it is capable of withstanding extreme temperatures. Speaking of its R-value, the material stands anywhere from R-3.1 to R-3.7.

5. Polyurethane Foam Thermal Insulation:

This material, often known as Spray Polyurethane Foam(SPF), is brought about by combining and subjecting it to the chemical reaction to create a foam. The mixing and reacting materials quickly react and expand as soon as they come in contact to form a foam capable of insulating, sealing air, and locking up moisture.

These are lightweight when contrasted with other materials, i.e., two pounds per cubic foot. As for the R-value, it is approximately R-6.3 per inch of thickness.

Thermal Insulation Benefits

Thermal Insulation has several benefits and so. A few of them are obvious and summarised hereunder:

1. Energy Efficiency:

The first and foremost benefit of installing thermal insulation material is that it uses the needed energy effectively and efficiently without compromising the comfort intended on providing you. This leads us to it, helping us minimize the energy that goes down in vain.

It can reduce energy expenses by 50% of structures where it has been installed. This makes sure to provide the residents/homeowners with enough heat with less energy consumption in winters.

2. Stronger and Long-Lasting Buildings:

Thermal Insulation helps abate heat movements across surfaces and vapor condensation. This, in turn, fends off situations of humidity, mold build-up, freezing, a deformation that could weaken the foundations of buildings, and the destruction of irons due to corrosion, thereby extending the lifespan of structures. Such an installation may prove to be earthquake-proof too, and there’s long-lasting durability.

3. Human Health Is Taken Care Of:

Careful and equal heat distribution between rooms and surfaces slightly enhances the comfort you may be yearning for, provided the Insulation has been laid out correctly.

As for the outsider side of buildings, such Insulation is conducive to better health by thwarting factors like humidity, mold, fungus, moisture, air pollution, and noise pollution, as these could severely affect you overall.

4. Shuts Down Sound Pollution:

Everyone has been through the problem of sound that impedes our progress and daily routine. Over here, thermal Insulation comes into the picture with its ability to reduce noise and weather effects that acutely affect us. Furthermore, applying such protective layers in building and structural gaps such as stairs and lifts prevents sound escape funnels.

5. Cuts Down on Various Expenses:

Once you get thermal Insulation installed, you will not have to worry about expenses of different sorts. As this shields your building from non-internal attacks, it is highly unlikely that you have to bear any cost relating to structural damages.

Another benefit would be that it significantly assuages fossil fuel import and foreign dependence on other countries. Now there’s minimal energy consumption, so you don’t have to rely on other countries to provide you with it. Overall, it helps by tapering unnecessary building energy and expenses on family health.

Also Read: What Is Foundation Spalling? | Foundation Spalling Repair Cost

Thermal Insulation Advantages and Disadvantages in Commercial Roofing

There are several advantages and disadvantages of installing thermal Insulation in commercial roofing. Due to the growing concern for energy efficiency, there is a pressing need for thermal Insulation for both builders and owners of these commercial structures.

The owners had one thing in their minds, and that was to maximize efficiency. Before anyone could advance any step in the same direction, each component of the existing roofing system was examined closely to tease out the correct thermal resistance figures.

Statistically speaking, the amount of money splurged in favor of space heating and cooling was 34% in 2012.

Roofs having thermal insulated don’t have to be at the receiving end of radiative losses in winters. Likewise, they don’t have to put themselves through scorching heat during summers as these insulated roofs wavers interior surface temperatures, thereby providing the occupants utmost comfort.

There are plenty of positives that come with the installation of thermal Insulation, and those are here under-discussed:

- Installation thermal insulation staves off the chances of condensation formation in the interior surfaces that are palpably exposed.

- The problem of temperature variations can spring from uninsulated walls or roofs. Upon installing thermal Insulation, the temperature of deck parts is neutralized by tapering temperature variations off.

- Such installation offers a flat surface that could be used up as a substrate for membrane installation covering those steel decks. An additional benefit would be fortifying the surfaces by laying up fire-resistant barriers.

- This also helps create a drainage system, especially in areas where the roof deck seems to be level. Maintain the desired temperature condition, and it ultimately saves the extra cost required.

- The building which is provided thermal Insulation requires very little power.

Under such a system, these thermal insulators are installed underneath the roof surface, which is pretty common globally, especially when concerned with low-slope roofs. This setup, however, can be disastrous and pose some challenges and obstacles for the roof surface, as discussed below:

It speeds up membrane aging: When these thermal insulations are installed directly under the roof, solar heat struggles to pass through the roof, making the room temperature shoot up. Because of this, the oxidation and evaporation of volatile oils in bitumen-based membranes pick up speed. Not only this, but one also finds crevices, weak and rifts on the walls and other surfaces, which could be attributable to ultraviolet radiation.

Once your layout these thermal insulations, the roof membrane expands and contracts due to the invariable changes in temperature. This consistent up and down of the temperature due to the lack of heat transmission through the roof can affect the rooms severely.

If we consider extreme heat during summers, the roof membrane that happens to be installed right next to the thermal insulator becomes hotter than expected. By dusk, the entire membrane temperature mixes back with the air temperature rather than the room’s interior.

This also results in the aging of the membrane, along with the formation of fissures and lap-shear stress. If this goes on for a long time, the Insulation may end up moving/shifting, which could easily be spotted with naked eyes.

No, the problem does not stop here. Rapid changes in interior and exterior temperatures due to the poorly and haphazardly installed can boost the chances of water vapor entering through the warm side and condensation build-up within the roof system.

It is taken as read that such type of locking of moisture can be extremely deadly, for it could vanquish thermal Insulation, make its way into the cracks and joints of the roof deck, causing the membrane to come apart due to freezing and thawing cycles.

To avoid such things, one must scrutinize for any sagging in the roof’s surface, efflorescence, and corrosion of the accessories of the roof like fasteners and others that hold it together. Moisture can sneak into the roof system while the thermal Insulation is installed or during servicing. One can foil it by proper ventilation and vapor barriers.

Conclusion

The article above talks about thermal Insulation and how it is installed conventionally. Further on in the article, we dove into its benefits and disadvantages when installed underneath conventional roof membranes. Run your eyes through the article to get your head around this.

What Is the Best Thermal Insulation Material?

The top three best thermal insulation materials are as follows:-

- Mineral Wool Thermal Insulation

- Fibreglass Thermal Insulation

- Polystyrene Thermal Insulation

What Insulation Material Has the Highest Thermal Resistance?

Urethane Foam

What Is Thermal Insulation?

The thermal insulation process limits the amount of heat transfer energy in any building in thermal exposure between objects in a range of radioactive effects.

What of Asbestos Is Found in Thermal Insulation?

Asbestos insulation is usually found in the less-visible parts of the home, including the following: Attics. Basements

What Is a Thermal Bridge in Building Insulation?

A thermal bridge, also called a cold bridge, heat bridge, or thermal bypass is an area or component of a material that has a higher thermal conductivity than the surrounding material, creating a path of minimal resistance to heat transfer.

What Is Thermal System Insulation?

Thermal system insulation is a material applied to a school building for heat loss or other purposes of pipes, breaching, tanks, fittings, boilers, ducts, or other internal structural components.

What Are Thermal Insulation Examples?

Examples of Thermal Insulators

- polystyrene foam.

- Fibreglass

- mineral wool.

- plastic.

Is Aluminum a Thermal Insulator?

Aluminum foil is a great insulator when used properly and is bad when used improperly. This material is a great reflector of thermal heat and also prevents evaporation and heat transfer as air / water cannot pass through it. But it conducts heat well so it will not be well insulated if it is in direct contact with an object.

How Does Thermal Insulation Work?

Thermal insulators prevent heat from moving from one place to another. There are 3 main ways to conduct heat: convection, conduction, and radiation. The term ‘thermal insulator’ usually refers to materials that impede conduction.

Which of the Following Would Have the Best Thermal Insulation Properties?

Some of the best thermal insulation materials, based primarily on thermal conductivity, include fiberglass, which is made of molten and fluffy glass threads, which do not conduct heat well.

Like this post? Share it with your friends!

Suggested Read –

- What Is Roof Eaves? | Different Types of Eaves Styles | Roof Eaves Repair Cost

- What Is Slurry Wall Construction? | Slurry Wall Construction Process

- What Is Metal Roof Insulation? | Metal Roof Insulation Options

- What Is Pointing? | Keyed Pointing | Tuck Pointing

- What Is Foundation Failure? | Signs of Foundation Failure | Causes of Foundation Failure

Skip to content

Skip to content