Type of Heavy Construction Equipment

Different type of heavy construction equipment is used in the construction industry.

Heavy construction equipment or heavy machinery is used in large projects to make the construction process easier and faster. Different types of heavy equipment are selected in a large project for different purposes.

The use of a type of heavy construction equipment depends on the size of the project and the economy of the project. Heavy equipment is used in construction for both large and small purposes.

Various Types of heavy construction equipment are used for building and structural construction, road construction, underwater, and other marine construction power projects, etc.

The use of construction equipment makes it easy to complete tasks like earth excavation and filling work, placement of building materials, compacting and leveling, etc.

Type of Heavy Construction Equipment

Type of heavy construction equipment can be classified into 4 main sections based on purpose and use as follows:

A. Earth Moving Equipment

1. Excavators

Excavators are one of the most important and widely used excavation tools in the construction industry. Their excavation can be done for general purposes. But apart from that, it is used for many purposes like heavy lifting, demolition, river dredging, tree felling, etc.

Excavators are made of long arms and cabinets. At the end of the long arm digging bucket, the machine is operated by the operator in the cabinet.

The excavator is construction-heavy equipment. Used to dig or move the earth in a large project. The excavator is mainly composed of 2 parts: first, the powerful hand is designed with an excavator bucket. The operator controls the powerful hand inside the small cabin.

The hydraulic system is used to control the mechanical hand of the excavator machine. It uses a chain wheel system to move the excavation process.

2. Backhoe

A backhoe is a tool commonly used for multiple purposes in construction. The front part of the backhoe can be used to shift the excavation clay by the bucket. This machine can be used for loading, and unloading by the front bucket.

Backhoe loaders are available in different size horsepower ratings ranging from 25 to 150. Up to 17 feet can be excavated by a standard backhoe. With an extensible dipper stick, the depth of digging by the backhoe can exceed 21 feet.

3. Graders

Graders are used especially for road construction. It is mainly used to level the ground surface for road construction. In this type of equipment, the horizontal blade is fixed between the front and rear wheels. The horizontal blades are carried up and down by the operating cabin.

Graders can be used for various purposes. These include leveling the ground surface before laying the asphalt, removing snow or dirt from the road, leveling the uneven soil, etc.

4. Bulldozers

A bulldozer is a type of digging tool that removes poor soil or rock layers. Which is removed by means of a large metal plate to give the soil a certain shape.

In bulldozers, a large metal plate with sharp edges is fixed at the front to move the clay. This plate is moved using a hydraulic piston.

5. Loaders

This type of heavy construction equipment is used at construction sites, especially for loading sand, and aggregate in hoppers in concrete mixer plants. In addition, loaders are used to load demolition waste, raw materials, and other materials into dumpers, trucks, etc.

Wheel loaders are widely used on construction sites. Track or crawl loaders are used in special situations when wheeled vehicles cannot reach the spot.

6. Skid Loader

A skid loader or skid-steer loader is a small, rigid-frame type engine-driven machine. In which loading of soil by lift arm and leveling by spreading the soil over the prescribed place. So that labor is saved.

Skid-steer loaders are usually of the four-wheel type. In which the wheels can mechanically operate on each side from full efficiency.

7. Dragline Excavator

The dragline excavator use in larger depth excavations in civil engineering and surface mining. In a dragline excavator dragline bucket is suspended on a long boom with wire ropes.

Excavation can be done by a dragline excavator in larger depths like underwater excavation, construction of ports, removal of silt in reservoirs, etc.

8. Trenchers

Trenchers or trenching machines are commonly used for laying pipelines in the ground, laying cables, digging trenches for drainage purposes. There are mainly two types of trenching machines. Chain trenchers and wheel trenches.

Trenchers of various sizes are determined based on the required width of the trench, depth, and hardness of the cutting surface. The wheel trencher is made of a toothed metal wheel.

Wheel trenchers are cheaper to operate and maintain than chain-type trenchers. It can easily work in hard or soft soils, The digging chain mounted with a round metal frame looks like a giant chainsaw. This type of trencher can cut the soil into narrow and deep trenches.

B. Material Handling Equipment

9. Tripper

The hydraulic system in the truck can raise the rear platform vertically at the front end so that the loading material in the truck is released by gravity which is also called tipper truck.

Tippers are used to carry bulk loads of construction and structural industries during mining and excavation operations. Which reduces the cost with high performance and long-term operation.

10. Dumper

Dump trucks are mostly used for transporting bulk materials used in construction.

The dumper is distinguished from the dump truck configuration based on the shape. A dumper is an open 4-wheeled vehicle with an unloading load in front of the driver.

The dumper is usually diesel-powered. It is used for secondary service as a site tractor. Provides uniform distribution of weight due to comparison of tires in the dumper.

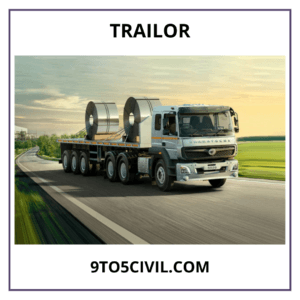

11. Trailor

A trailer is usually a disabled vehicle with a long span that is pulled by a powered vehicle. It is commonly used for transporting materials.

People used mobile homes with limited living facilities in long trailers while traveling.

Typically, trailers are used for the transportation of materials used in construction. Trailers are used for the transport of RCC pipe, water GI pipe, heavy machinery.

12. Tower Crane

This type of heavy construction equipment is used in high-rise building construction. This type of tower crane can be used to move heavy materials like pre-stressed concrete blocks, steel trusses, frames, concrete hopper, scaffolding material, etc. easily to the required height.

A crane is a type of lifting type machine in construction. The tower crane is fixed on the ground with the proper foundation. It is used to move and lift the material horizontally over the designated location at the construction site and to transport it to other locations.

13. Wheel Tractor Scrapers

Wheel tractor-scraper is a type of heavy equipment used in construction. This type of equipment is mounted on a pan/hopper for loading and carrying materials. It cuts the ground horizontally through the front cutting edge.

This type of equipment is driven by a wheel tractor vehicle at the front and a scraping arrangement for cutting clay at the rear.

The front blade of this type of equipment is lowered to the ground and moving the equipment starts digging the ground above. The excavated clay is then collected in a hopper by a conveyor belt system. When the hopper is fully filled, the hopper is unloaded at the clay dump yard.

14. Compactor

Compactors or rollers are used in road construction to compact materials or earth surfaces. Different compactors are available for different compacting purposes as per requirement.

Smooth wheel rollers are commonly used in road construction to compact shallow layers for soil or asphalt etc.

Sheep-foot rollers are used for deep compaction purposes in special circumstances.

Pneumatic tyred rollers are used especially in bituminous road construction to compact fine gravel and asphalt layers etc.

15. Telehandlers

Telehandlers are used in large building projects to lift material to a limited height. Through it the material can be lifted and transported. This type of equipment has a long telescopic boom through which the material can be sent back and forth to the right place.

16. Paving Machine

Paver or asphalt pavement is used for road construction. The Paving Machine is continuously loaded with the asphalt mixture prepared by the dump truck in a feeding bucket and the paver machine distributes the prepared asphalt mixture evenly over the road surface with compaction. Asphalt road prepared by paving machine requires roller compaction.

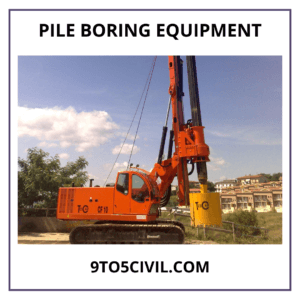

17. Pile Boring Equipment

Pile boring equipment is usually used for pile foundation of bridge construction. In which bore hole is prepared at the foundation place of the bridge by this type of equipment.

18. Pile Driving Equipment

Pile driving equipment is used for the construction of the pile foundation used at the construction site. This type of equipment lifts the precast pile. And takes it to the required depth in the soil in the right position.

Piling rigs, piling hammers, hammer guides, etc. are used in various types of pile driving equipment.

Also Read : What Is Pile Foundation? | Uses of Pile Foundations | Types of Pile Foundations |

Like this post? Share it with your friends!

Suggested Read –

- The Standard Room Size & Location In House | Standard Room Size for Drawing or Living Room | Standard Size Of Bedroom | Standard Room Size for Kitchen | Standard Size Of Bathroom

- What Is CMU Wall? | Characteristics of CMU Block | CMU Block Dimensions | CMU Retaining Wall Construction | CMU Block Shapes | CMU Block Weight | Advantages & Disadvantages of CMU Walls |

- What Is Construction Cost Estimate? | Type of Construction Cost Estimate | Advantage of Construction Cost Estimate | Disadvantage of Construction Cost Estimate

- What Is Residential Building? | Types of Residential Buildings | Site Selection for Residential Buildings

- Types of Beams in Constructions

Frequently Asked Questions (FAQ)

Type of Heavy Construction Equipment

1. Excavators

2. Backhoe

3. Graders

4. Bulldozers

5. Loaders

6. Skid Loader

7. Dragline Excavator

8. Trenchers

9. Tripper

What Is Heavy-Duty Equipment?

Heavy equipment or heavy machinery refers to heavy-duty vehicles, specially designed for executing construction tasks, most frequently ones involving earthwork operations or other large construction tasks. The term “plant” is used to refer to any mobile type of heavy machinery.

What Is Considered Construction Equipment?

According to Wikipedia, heavy equipment is defined as: They are also known as, construction equipment, construction plant, earth movers, engineering vehicles, or simply equipment. They usually comprise five equipment systems: implement, traction, structure, power train, control, and information.

How Much Do Excavators Cost?

A new full-sized excavator costs anywhere between $100,000 and $500,000 or more. A small-sized excavator weighing 10 to 15 tons costs anywhere between $75000 – $150,000. However, a used full-sized excavator will cost 25% to 40% less than the original price and you can expect to pay $50,000 to $60,000 or more.

What Are Excavators Used For?

Excavators are primarily used for landscaping, digging holes and trenches, lifting and placing large objects, and demolishing structures. Other tasks can also be accomplished by using hydraulic attachments such as grapples or augers.

What Does an Excavator Charge Per Hour?

An excavator operator’s average cost is between $20 and $50 per hour. However, many exactor rental companies include the operator fee in their rental prices. This accounts for the cost of moving the heavy equipment from the rental company to the client’s construction site.

Do Excavators Make Good Money?

The salaries of Excavator Operators in the US range from $26,670 to $98,000 , with a median salary of $40,050 . The middle 60% of Excavator Operators makes between $40,050 and $55,739, with the top 80% making $98,000.

Why Do We Need Excavators?

Excavators are popular earthmoving vehicles that feature a bucket, arm, rotating cab, and movable tracks. These components provide superior digging power and mobility, allowing this heavy equipment to perform a variety of functions, from digging trenches and breaking holes to lifting away waste and excavating mines.

Why Do We Use Excavators?

An excavator is a construction vehicle used to excavate or move large objects. … The excavator uses a Hydraulic system to generate a Hydraulic force to control the mechanical arm of the machine. It also uses a chain wheel system for its movement. Excavators are been used in large and small scale constructions.

How Much Does a Used Backhoe Cost?

Mini or Small Backhoes – Models that can dig between 9 and 10 feet typically cost $25,000 to $35,000. Large Backhoes – Models that can dig between 15 and 16 feet typically fetch $75,000 to $110,000. Larger Backhoes – Any model over 16 feet tends to cost well over $100,000.

What Is a Backhoe Good For?

Backhoe loaders can tackle landscaping jobs of all sizes and types, such as digging up trees and moving them to new locations, even keeping the root balls intact. Backhoes are also great for digging fence post holes or minor excavation jobs, such as digging small ponds and water features.\

How Deep Can You Dig with a Backhoe?

Digging capacities are more varied, with the most common class of backhoes providing a depth of 14 to 15 feet. A second, larger class of machines has a 15- to 16-foot depth.

How much is a 2020 backhoe?

Backhoe loaders with a dig depth of 9 to 10 feet usually cost $25,000 to $35,000. Machines with a 14-foot dig depth – the industry standard – and horsepower between 70 and 90 costs anywhere from $50,000 to $90,000. Slightly larger models with dig depths of 15 to 16 feet run $75,000 to $110,000.

Skip to content

Skip to content