What Is Vacuum Concrete?

Vacuum concrete is the water removed by vacuum pressure after the concrete has been placed in the structural member. Vacuum concrete has higher strength and durability than ordinary concrete.

In the concrete mixing process, more water is added to make the concrete more efficient. Therefore excess water is not required for a complete hydration process. Excess water is removed from the concrete by vacuum pump by vacuum concrete technique. So that the concrete can be strengthened before it hardens.

The excess water-cement ratio for concrete is detrimental to strength. The water-cement ratio in Concrete must be as required to obtain high strength.

Vacuum concrete is a technique of removing excess water from efficient concrete using a vacuum pump.

Vacuum Concrete Vs. Traditional Concrete

Vacuum concrete and conventional concrete are two different types of concrete. Which differ in production methods, properties and applications. Here is a comparison between vacuum concrete and conventional concrete:

1. Production Method:

Vacuum Concrete: In vacuum concrete, the mixture is prepared under low pressure using a vacuum chamber or a pump. This process helps remove excess water and air from the concrete mix, resulting in a denser and more compact final product.

Traditional Concrete: Conventional concrete is produced by mixing cement, aggregate (such as sand and gravel), water, and sometimes admixtures or admixtures. The mixture is usually prepared at ambient pressure without the use of vacuum.

2. Strength and Durability:

Vacuum Concrete: The vacuum process in vacuum concrete helps achieve better compaction and reduces the presence of voids, leading to higher strength and durability. Vacuum concrete often exhibits improved resistance to cracking, water permeability, and long-term performance.

Traditional Concrete: Conventional concrete can provide adequate strength and durability when mixed, placed and cured properly. However, it may have a high probability of having voids, which may affect its long-term performance.

3. Functionality:

Vacuum Concrete: Vacuum concrete may have slightly different performance characteristics compared to conventional concrete. Reduced water content and improved compaction can result in stiffer mixes, requiring careful handling and possible adjustments to mix design.

Traditional Concrete: Traditional concrete offers a wide range of performance options, allowing for easy placement and finishing. Water content and mixing can be adjusted to achieve the desired consistency.

4. Applications:

Vacuum concrete: Vacuum concrete is often preferred in applications where high strength, durability and low permeability are important, such as in high-rise buildings, tunnels, marine structures and infrastructure projects.

Traditional Concrete: Conventional concrete is widely used in various construction applications including foundations, slabs, columns, beams and general structural elements.

It is important to note that the choice between vacuum concrete and conventional concrete depends on specific project requirements, cost considerations and engineering recommendations. Consultation with construction professionals or engineers is recommended to determine the most appropriate concrete type for a given project.

Vacuum Concrete Benefits

The water-cement ratio of 0.38 is required for the chemical reaction of cement with water; the water-cement ratio taken more than this amount mainly affects the efficiency required for the concrete, so the concrete can be easily placed in the formwork without honeycombing.

As the efficiency of the concrete is satisfied, this excess water will evaporate out, leaving capillary holes in the concrete, which reduces the high permeability and strength in concrete. Thus the efficiency and high strength of concrete are contradictory.

The vacuum concrete method is an effective technique used to meet the requirements of efficiency and high strength. This requirement of concrete can be made possible both at the same time by using this technique.

Using this technique, the excess water remaining after placement and compaction of the concrete is removed using a vacuum pump. This technology usually works effectively in industrial units, parking lots and deck slabs of bridges etc. This technique can only reduce the surface area of concrete to a depth of 100 to 150 mm.

History of Vacuum Concreting

The technique of vacuum concreting was first used by Sweden’s Trimix AB to increase strength by removing water through a vacuum pump in concrete.

The technique became popular in the United States and has since gradually gained popularity throughout Europe.

This technique is commonly used in concrete works in Sweden.

In India, the details of this technology were introduced in 1987 by Aquarius Technologies.

Also Read : What Is False Work? | Types of Falsework | Causes of Falsework Failures

Properties of Vacuum Concrete

- The strength of concrete can be increased by about 25% by using the vacuum concrete technique.

- The vacuum increases the density of concrete by using concrete techniques.

- The permeability of concrete can be reduced by using the vacuum concrete technique.

- The durability of concrete can be increased by using the vacuum concrete technique.

- The abrasion resistance of concrete can be increased by using the vacuum concrete technique.

- The impact resistance of concrete can be increased by 10% by using the vacuum concrete technique.

Vacuum Concrete Applications

- The vacuum concrete technique is mainly used in hydropower plants.

- Suitable for cooling towers as vacuum concrete application.

- The vacuum concrete technique can be used for industrial and cold storage floors.

- The vacuum concrete technique is commonly used for ports and harbours.

Also Read : What Is Monolithic Slab? | What Is Floating Slab? | Difference Between Floating Slab and Monolithic Slab

Advantages of Vacuum Concrete

Some of the advantages of using the vacuum concrete technique are as follows,

- The use of the vacuum Concrete technique increases the strength of concrete and, at the same time, reduces the permeability of concrete.

- The use of vacuum concrete techniques improves the quality of durability and density. It also reduces voids in concrete.

- The curing period can be reduced by using the technique of vacuum concrete. If the concrete has a curing period of 1 week, it can be reduced to 3 days.

- The vacuum concrete technique can be used to remove formwork before it is time to remove formwork for concrete slabs because concrete is able to gain strength quickly. So this vacuum concrete technique can be used in repetitive tasks.

- High strength and high efficiency of concrete can be achieved by using the vacuum concrete technique.

- The use of the vacuum concrete technique increases the final strength of concrete by 25%. (Which increases the resistance of concrete to shrinkage and tensile strength.

- The use of the vacuum concrete technique increases the bonding strength by about 20%, which forms a strong bond with the elements of concrete.

- With the use of vacuum concrete technique, the work of the structure of the building can be achieved faster earlier.

- The use of vacuum concrete provides easier and more efficient compaction of concrete.

- The vacuum concrete method creates a pet-free surface on the surface of the concrete.

- The top surface of the concrete with the vacuum concrete method has a very high resistance to abrasion. So this technique can be used especially for floor in road and industrial.

Also Read : What Is Lintel? | Size of Lintel Beam | Purpose of Lintel | Types of Lintel | Advantages of Lintel Beam

Disadvantage of Vacuum Concrete

- This method uses power for the dewatering pumps, which increases the total cost.

- The initial cost of equipment for the vacuum concrete technique is high.

- Various special equipment is required for vacuum concrete.

- The process for vacuum concrete requires skilled labour.

- The vacuum concrete technique used is suitable for concrete with a water-cement ratio greater than 0.4. This technique is not used for a lower water-cement ratio than that.

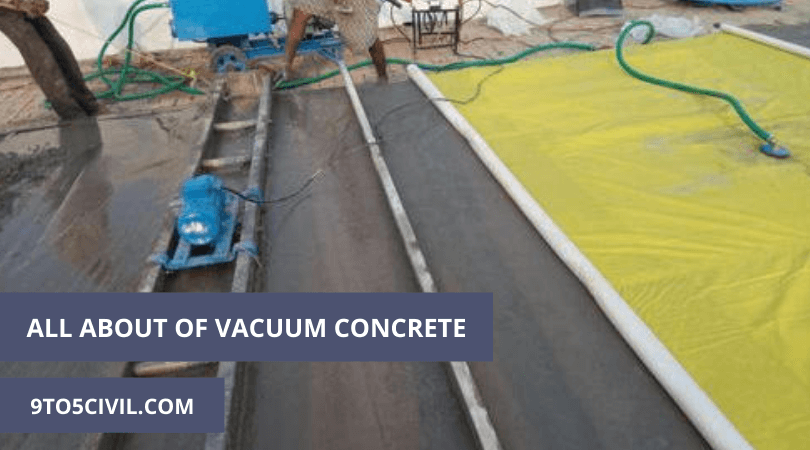

Equipment Required for Vacuum Concrete Method

Vacuum concrete is obtained using the following tools,

- Formwork

- Vacuum Pump

- Filtering Pad

- Suction Mat

- Power Trowel

- Power Float

- Double Beam Screed Vibrator.

1. Formwork

The vacuum concrete technique usually involves preparing formwork for concrete using ms channels, which allows the stopper and screed vibrator to operate safely over it.

2. Vacuum Pump

This method uses an electric motor of 5-10 horsepower for vacuum.

3. Filtering Pad

Fixing is done with a rubber seal around the filtering pad. The minimum dimension of the filtering pad is kept at 90cm x 60cm. Includes backing piece and rubber seal as filtering pad.

A minimum size 90 * 60 cm mat is placed on the surface of the concrete. However, the use of small mats to create a vacuum should be avoided.

4. Suction Mat

The mats are fixed on fine filter pads to prevent cement slurry with water.

It is on a large single PVC sheet concrete. Nylon fabric acts as a filter. The top surface of the mat has a hose with a junction box.

5. Power Trowel

The water suction process forms capillaries in concrete, which is made by extracting water from concrete, which is detrimental to the strength of the concrete. Therefore power trowel is used to improve the condition of such concrete, which fills the cracks of concrete by vibration.

6. Power Float

It is used for finishing the surface of the concrete, which increases the strength of concrete.

7. Double Beam Screed Vibrator

It is a 12.5 kg electric powered vibrator for the compaction of concrete.

Vacuum Concrete Process

- The efficiency of ordinary concrete depends on the amount of water in the concrete, which is the main factor to speed up the construction. Therefore it is advisable to use vacuum concrete techniques to compromise the efficiency and strength of concrete.

- In the vacuum concrete process, the conditions for the vacuum are created on the top surface of the concrete.

- In vacuum concrete processing, a certain amount of water is removed from the concrete to a certain depth.

- Porous mats are placed on the surface of the concrete to create a vacuum, which is connected to the scheme of pumping water out through a vacuum pump.

- Which reduces the amount of water from the concrete through the vacuum pump. And the concrete gains strength.

- The concrete surface obtained by vacuum concrete has high strength capacity, low permeability and high durability, which is suitable for the use of concrete.

Like this post? Share it with your friends!

Suggested Read –

- What Is MDF? | MDF Board Uses | MDF Board Properties | Application of MDF Board |

- What Is Standard Brick Size? | What Is Frog? | Importance of Brick | Brick Dimensions Inches | Brick Standard Dimension and Size

- What Is Kitchen Layout? | Type of Kitchen Layout | Advantage & Disadvantage of Kitchen Layout

- Important of Cement Test | Type of Cement Test

- What Is Modified Proctor Test? | Purpose of Modified Proctor Test | Modified Proctor Compaction Test Apparatus | Modified Proctor Test Procedure | Calculation of Modified Proctor Test | Difference Between Standard Proctor Test Vs Modified Proctor Test

Best Vacuum For Concrete Floors For 2023

- Bissell Hard Floor Expert Multi-Cyclonic Bagless Canister Vacuum

- Dyson Ball Animal 2 Upright Vacuum

- Shark Navigator Lift-Away Professional Vacuum

- eufy by Anker, BoostIQ 15C Robotic Vacuum

- Shark ION F80 MultiFLEX Cordless Stick Vacuum

What Is the Vacuum Concrete Technology?

The vacuum dewatering concrete is based on the principle of removing surplus water (or excess water). The concrete floor is dewatered by vacuum process wherein surplus water from the concrete is removed immediately after placing and vibration, thereby reducing the water cement ratio to the optimum level.

Can You Vacuums for Concrete Floors?

Yes, you can. Many people with concrete floors prefer to clean them using a two-step process. First, they vacuum the floor to remove dirt and debris and then follow that by mopping for a thorough clean.

What Is Vacuum Dewatering Concrete?

The vacuum dewatering concrete is based on the principle of removing surplus water (or excess water). The concrete floor is dewatered by vacuum process wherein surplus water from the concrete is removed immediately after placing and vibration, thereby reducing the water cement ratio to the optimum level.

Vacuum Concrete Cost

Vacuum concrete can cost anywhere from $150 to $250 per cubic yard. There may be price increases for labor and other project-specific costs. These costs include the materials, equipment and techniques required for the vacuum concrete process.

Vacuum Concrete Vs. Traditional Concrete

The choice between vacuum concrete and conventional concrete depends on specific project requirements, cost considerations and engineering recommendations. Consultation with construction professionals or engineers is recommended to determine the most appropriate concrete type for a given project.

Skip to content

Skip to content