What Is Shoring?

Shoring is a temporary structure used for construction. When a structure such as a building, ship, structure, etc., is in danger of collapsing or during repairs, a method like shoring temporarily supports the building, ship, and trench.

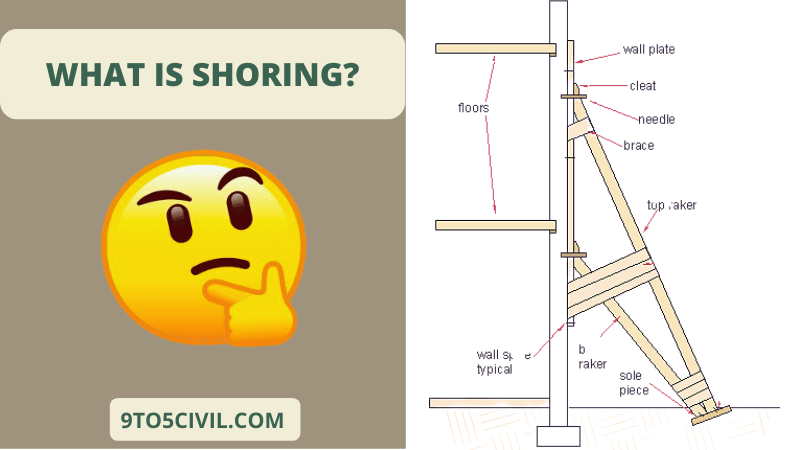

This method is used to support an unprotected wall through the use of incline members called rackers.

What does Shoring Mean?

Shoring is a form of support for the inclined member, which is usually used as a temporary. Used for various purposes during repair or original construction of buildings and during excavation. Such as temporary support may be needed to relieve loads on a masonry wall.

Also Read : What Is a Cantilever Bridge? | Type of Cantilever Bridges | Advantages & Disadvantages of Cantilever Bridge

What Is the Use of Shoring?

Shoring is used in different situations as follows,

- Shoring is used to support the stability of construction when a risk-like situation has arisen due to uneven settlement at its foundation.

- Demolition of the side building uses shoring to stabilize the existing building.

- Construction stability is at risk due to poor workmen ship and old construction.

- The structure is unsafe due to ongoing repairs in the existing construction.

- In addition, shoring is used to support the structure during improvements such as the demolition of old walls and perforation.

Type of Shoring

Each Shoring system has its own specificity to perform its function. And it depends on the principles of different situations according to the function of shoring.

Various Shoring components include rackers or inclined members, wall plates, needles, cleats, bracing, sole plates, etc.

The inclined member with the base plate is set on the ground, and the racker is bent at 30 angles. It helps to fix the member inclined by cleats and dogs on the ground.

The type of shoring are classified as follows,

- Dead Shoring

- Raking Shoring

- Flying Shoring

1. Dead Shores

Dead Shoring is used to support dead loads of a structure.

Dead Shoring is a system of shoring that works to support dead loads such as walls and ceilings, floors, etc. This type of shoring provides wall openings and rebuilds the wall by removing defective old load bearings. Or it supports the structure to form a new wall by removing the lower part of the wall.

The dead shore is made up of different parts. There is a precise arrangement of beams and posts as required so that the weight of the structure above it can be supported and can be safely transferred to the ground at the base.

When the wall is to be opened, the holes in the wall should be made as per the instructions. So that there is enough space when fixing the beam or girder. This is because the beam is permanently fixed to carry the weight of the structure.

- Holes are made depending on the type of masonry. Usually varies from 1.2 m to 1.8m center on the wall. A beam called a needle is inserted into these holes, and the needle is supported on both sides of the wall by vertical props at their ends.

- These vertical props are also called the dead shore. The needle can be made of timber or steel material. And the needle is sufficiently supported as required to carry the load above.

- The dead shore is fixed to the needle and props position, allowing the workspace to stand on either side of the wall. The props are fixed tightly by a folding wedge at their base. While the junction between the props and the needle is provided strong with the help of dogs.

- Before starting the demolition work of the building, all the opening spaces of doors, windows, etc., are fixed by a strut. The load walls of the upper floors and roof are well supported by independent shoring.

- After completing the building work, it is advisable to keep the shoring support for at least seven days before dismantling so that the members created for the structure have enough strength to be self-supporting.

2. Raking Shores

In this method, the inclined member is used to support the wall. This inclined member is known as a raker. The racking shore consists of rakers or inclined members, wall plates, needles, cleats, bracing, and soleplate.

The wall plate is about 20 to 25 cm. Fixed in a vertical position with a wall face 5 cm wide and 5 to 7.5 cm thick. And it is protected by a needle (10 cm x 7.5 cm).

The needle is about 10 cm. Inside is laid in the wall. The needle supports the racker. The wall plate is fixed directly to the wall using nails through the cleats.

The rakers are fixed in such a way against the needle that is in the center. As a result, the racker line meets the wall at floor level. Thus, a racker is fixed to each needle as required.

These rakers are fixed with inter-connected struts to prevent buckling. Then, with the help of an iron dog, the legs of the rackers are fixed on a single base plate embedded in the ground.

The legs of the rakers are fixed with the help of a hoop iron near the soleplate. Acts to distribute the pressure on the wall evenly through the wall plate.

Points to Keep in Mind for Raking Shoring in Construction

- The length of the racker can be reduced by introducing a rider racker for high-rise buildings.

- The rackers should have an incline on the ground by 45 degrees to work more effectively. However, in practice, the angle can vary from 45 to 75 depending on the wall support. But usually, the top racker is kept below 75 degrees.

- The rider should be braced properly at intervals as required.

- The size of the rackers should be chosen according to the resistance of the maximum force coming through the walls or structure.

- In the shoring system, the centerline of the racker and the wall should be at floor level.

- The shoring can be supported at a distance of 3 to 4.5 m to cover a longer length.

- The inclination on the sole plate must be properly embedded in the ground. And for that, the soleplate should be used in the right section and size.

- Wedges should not be used in shoring sole plates. Because it gives way during vibration.

Also Read : What Is Pitched Roof? | Types of Pitched Roof | Advantage & Disadvantage of Pitched Roof

3. Flying or Horizontal Shores

This shoring is used to support two adjacent parallel walls. In which the wall of the central building has become unsafe due to removal or cracking

All the necessary arrangements to support an insecure structure do not reach its support ground in this type of shoring.

The flying shore uses wall plates, needles, cleats, horizontal struts (commonly known as horizontal shores), and inclined struts arranged. It is used in different situations.

Even in this system, the wall plates are protected by a vertical fix against the wall.

A double flying shore is used when the distance between the walls is greater. The main advantage of flying shore is that it does not obstruct ground-level traffic for building work.

Also Read : What Is Fire Escape Staircase? | Types of Fire Escaping Stairs | Fire Escape Staircase Regulations

Points to keep in mind for flying shoring in construction

- The centerline of the flying shore and the struts should meet at the floor level of those two buildings.

- If the floor level is different then the horizontal shore should be placed between the two-floor level having equal strength.

- The struts should be 45 degrees with a horizontal shore. In any case inclination, this strut is held up to 60 degrees with the horizontal shore.

- Single shore should be used up to a distance of 9 meters between the walls of two buildings and a double shore system should be used when the distance is more than 9 meters.

- Flying shore is included when repairs are carried out in an older building. And should be kept in place until the construction of the new unit of the building is completed.

Like this post? Share it with your friends!

Suggested Read –

- What Is Isometric Projection? | Principle of Isometric Projections | Isometric Scale | What Is Isometric Drawing? | Methods of Isometric Drawing

- What Is Chain Surveying? | Principle of Chain Surveying | Instruments Used in Chain Surveying | Technical Terms of Chain Surveying | Procedure for Chain Surveying | Advantages & Disadvantages of Chains in Surveying

- What is a Short column? | What Is a Long Column? | Difference Between Short Column and Long Column

- Top Construction Companies in the USA

- What Is Concrete Frame? | What Is Precast Concrete Frames? | The Components of Concrete Framed Structures | Advantage & Disadvantage of Concrete Framed Structure

Skip to content

Skip to content