Introduction of Beam

Different types of beams are used as required in the construction of buildings and structures to withstand the vertical load, shear force, and bending moments of horizontal structural elements on the building. The beam transfers the load to the foundation through the walls, column.

In the article, we will learn about the different types of beams used in building construction. The type of beam is characterized by support position, cross-section shape (profile), length and material, etc.

Also Read : What Is Beam? | What Is Column? | Difference Between Beam and Column

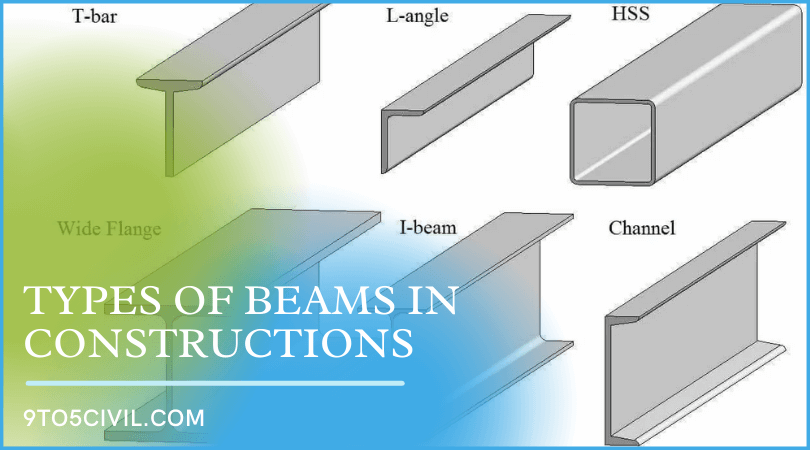

Types of Beams in Constructions

Different types of beams are classified on the following basis

Based on Construction Materials

- Reinforced Concrete Beams

- Timber Beams

- Steel Beams

- Composite Beams

Based on Shape Of Cross Section

- Rectangular Beam

- T-Section Beam

- I – Beam

- L-Section Beam

Based on Support Conditions

- Fixed Beam

- Simply Supported Beam

- Overhanging Beam

- Cantilever Beam

- Continuous Beam

Based on Geometry

- Straight Beam

- Tapered Beam

- Curved Beam

Based on Equilibrium Condition

- Statically Determinate Beam

- Statically Indeterminate Beam

Based on Method of Construction

- Cast In-situ Concrete Beam

- Prestressed Concrete Beam

- Precast Concrete Beam

Also Read : What Is a Beam Bridge? | Types of Beam Bridges | Advantage & Disadvantage of Beam Bridge

Types of Beam: Based on Construction Materials

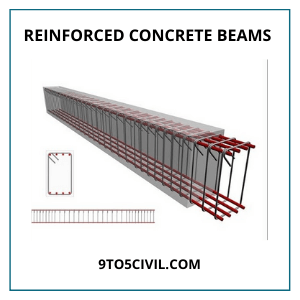

1. Reinforced Concrete Beams

- Reinforced concrete (RC) is made using composite material such as concrete and reinforcement. This type of beam is placed for reinforcement due to the low tensile strength and flexibility of the concrete. Thus, higher tensile strength or ductility can be obtained by providing reinforcement as required in this type of beam.

2. Timber Beams

- Nowadays, timber is used for decoration in the modern construction industry. Its use is avoided for the construction structure of the building. Due to the easy availability of wood in the village, wooden beams of the past are used.

- The timber beam needs to be maintained properly from time to time. Therefore, timber beam can be a strong and durable building material for the structure if it is periodically inspected and maintained.

- However, due to the various advantages of concrete beams, the use of timber for building materials is limited.

Also Read : Cantilever Beam | Advantages of a Cantilever Beam | Disadvantage of the Cantilever Beam

3. Steel Beams

- Steel beams are made from raw steel material to support structural heavy loads. The use of steel beams has higher strength and inertia than concrete beams in the structure of a building. Steel beams are manufactured in the factory in different shapes and sizes according to the construction.

- Steel beams are used in various steel structures. Structures such as workshops, steel roofs, trusses, and bridges, etc., can be constructed.

4. Composite Beams

- This type of beam is made as a structural member using more different materials, which are used in the structure of buildings to jointly act as a unit. In some building structures, steel-concrete composite beams are used to obtain strength and ductility as required.

- Composite beams can be made using materials such as steel-wood, wood-concrete, and plastic-concrete.

Also Read : What Is Lintel? | Size of Lintel Beam | Purpose of Lintel | Types of Lintel | Advantages of Lintel Beam

Types of Beam: Based on Shape Of Cross Section

5. Rectangular Beam

- The cross-section of the rectangular beam experiences tension at the bottom of the beam and compression at the top.

- Therefore, more reinforcement is given at the bottom than in the upper part of the cross-section of the beam. Rectangular beams are most commonly used in building construction.

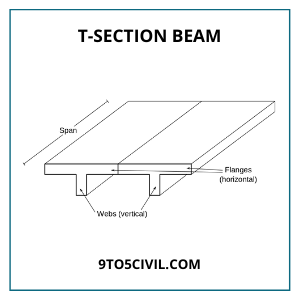

6. T-Section Beam

- T-beams can be made of reinforced concrete or wood with a T-shaped cross-section in construction. The top of the T-shaped cross-section in construction resists compressive stress as a compression member. In the T beam, the web (vertical section) of the beam below the compression flange resists shear stress and bending.

Also Read : What is the Plinth Beam? | Application of Plinth Beam | Specification of Plinth Beam | Plinth Protection

7. I – Beam

- I beams are used in the construction of steel structures. I beams can safely resist deflection and bending moments in steel structures.

- I section beams are made as per the requirement prepared in the factory. I section beam consists of the top flange, web, and bottom flange.

- I beam Section is used in critical support trusses in buildings. The I beam ensures the integrity of the structure with greater strength than other beam sections.

8. L-Section Beam

- L – The beam is monolithic with a concrete slab in a reinforced concrete structure. This type of beam is used as a beam around a stair or lift opening. L-beam is a component of the structure of a building with slabs.

- The L-beam is usually provided around the perimeter of the slab.

Types of Beam: Based on Support Conditions

9. Fixed Beam

- Both ends of this type of beam are fixed. In addition, the rotational movement in the fixed beam is controlled. Since the fixed beam is fixed at its ends, its end cannot be rotated.

- The fixed beam is placed to resist intense pressure. This type of beam does not produce any reaction. It is used in high-rise buildings and industrial construction.

10. Simply Supported Beam

- The simple structural elements of this type of building rest on both end bases. But this type of beam has pinned support at one end and roller support at the other end. In addition, this type of beam resists shear stress and bending moments.

11. Overhanging Beam

- This type of beam is usually a simple supporting beam-like structure. But in an overhanging beam, one end extends some distance from the support.

- Typically, the beam is given to each end to transfer the load through the column. In an overhanging beam, one end of the beam is supported by a column, and the other end is overhanged away from the support.

- Overhanging Beam is commonly used in residential buildings designed to create shades or balconies.

- The Double Overhanging Beam has overhanging at both ends, slightly away from the support.

12. Cantilever Beam

- In this type of beam, one end of it has a fix. And the other end is free. Cantilever beams are used especially for parking and sheds of the railway station.

- Cantilever beams are widely used in the construction of residential buildings, especially cantilever bridges and balconies.

13. Continuous Beam

- A type of beam that has two or more supports in a beam is called a continuous beam.

- This type of beam is also known as a continuous beam. In which the beam is supported on both ends with additional intermediate support.

- This type of beam has more than one span in a building. The use of continuous beams is usually preferred for bridge construction.

Types of Beam: Based on Geometry

14. Straight Beam

- A straight beam is the same as a straight profile with a length. Most high-rise buildings are built using straight beams.

15. Tapered Beam

- The cross-section of this type of beam is tapered.

16. Curved Beam

- This type of beam is made on the balcony of a building with a curved profile.

Types of Beam: Based on Equilibrium Condition

17. Statically Determinate Beam

- The support reaction developed in this beam is calculated based on the basic equilibrium state. Statically determinate beams are analyzed using the basic equilibrium position to be used as a beam.

- In this type of beam, the number of unknown forces in a statically defined beam is equal to the number of equations.

18. Statically Indeterminate Beam

- For static indeterminate beams, the number of strangers exceeds the number of equations. As a result, the equilibrium state is not sufficient to resolve the reactions. Therefore, analyzing this type of beam is more complex than statically defined beams.

Types of Beam: Based on Method of Construction

19. Cast In-situ Concrete Beam

- This type of beam is made by the proper fixing of the formwork on the project site. Therefore, proper formwork is fixed for the beam. Then, fresh concrete is poured into it. During this concreting, compaction is done in the beam by a suitable vibrator machine.

20. Prestressed Concrete Beam

- Before placing this type of concrete beam in position, stress or strain is applied to it.

- Prestressed-concrete beams designed by engineers can extend a greater distance than reinforced-concrete beams. This type of beam is thin, light in weight.

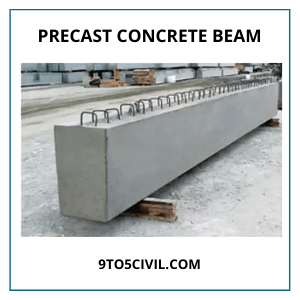

21. Precast Concrete Beam

- Precast beams are made in the manufacturing plant. It is manufactured in a highly controlled environment and in ideal conditions for maximum beam strength.

- The precast concrete beam is made in a very controlled manner with high quality. These finished precast beams are transported to the construction site for use.

Like this post? Share it with your friends!

Suggested Read –

- What Is Pier and Beam Foundation? | Advantages &Disadvantages of Pier and Beam Foundations | Difference Between Pier and Beam Foundation Vs Slab Foundation | Pier and Beam Foundation Cost

- What Are Curb and Gutter? | Difference Between Curb and Gutter | Types of Curb and Gutter | Construction of Curb and Gutter | Advantages of Curb and Gutter

- What Is Retaining Walls? | Uses of Retaining Wall | Types of Retaining Wall | Advantages of Retaining Wall

- What Is Shear Wall? | Purpose of Shear Wall | Function of Shear Wall | Types of Shear Wall | Advantages & Disadvantages of Shear Wall | Application of Shear Wall

- Type of Window | Criteria for Selecting the Suitable Window from Different Types of Windows

Skip to content

Skip to content