What Is CMU Wall?

A concrete masonry unit (CMU) is used in building construction as a standard-sized rectangular block. CMU is used as one of the most versatile building products due to its variety of looks.

The CMU wall is known as the concrete masonry units wall. Which are used as building products for a variety of environmentally friendly applications. These blocks are used in interior walls, as part of attractive exterior design.

Using the CMU blocks in various applications used in the project can contribute to a “green” building. The CMU block is made of cast concrete. It is made by mixing Portland cement and aggregate, sand, and gravel.

The use of concrete blocks with lightweight simplifies the masonry work of the building. The strength of the CMU wall can be increased with horizontal or vertical reinforcement in CMU block construction.

Lower density blocks can be made using industrial waste. Recycled materials such as fly ash or bottom ash can be used to form CMU blocks.

Characteristics of CMU Block

The CMU block is made from a suitable mixture of Portland cement, aggregates, and water. Its use as a building material gives concrete designers and builders some attractive characteristics. These characteristics are as follows,

- Durable

- Fireproof

- soundproof

- Easy to install

- Low maintenance

- Decorating can be finished. Decorative after installation can give effect.

The standard size of a concrete block (CMU) is usually 8 ”x 8” x 16 ”. But its actual size 7 5/8 ”x 7 5/8” x 15 5/8 ”block size is used in building construction. Which is kept a little smaller in size for the mortar.

CMU Block Dimensions

CMU blocks are made in different sizes and shapes. CMU blocks are distinguished by their different thickness. For example, a 6 ″ thick concrete block is commonly used for a 6 ″ CMU wall. Similarly, 10 ″ thick concrete block is usually used for masonry work of 10 ″ CMU wall.

These types of concrete blocks are available in half sizes, which helps to reduce the need to cut blocks at the end of the walls. Architects always try to reduce a dead load of buildings by using trivial dimensions for the building.

Some of the nominal and actual sizes of CMU blocks used in building construction are listed below.

Commonly used CMU blocks include standard sizes 4 ″, 6 ″, 8 ″, 10 ″ and 12.

| CMU Blocks Size | NOMINAL DIMENSION D x H x L |

| 4” Full CMU Blocks | 4″ x 8″ x 16″ |

| 4” Half CMU Blocks | 4″ x 8″ x 8″ |

| 6” Full CMU Blocks | 6″ x 8″ x 16″ |

| 6” Half CMU Blocks | 6″ x 8″ x 8″ |

| 8” Full CMU Blocks | 8″ x 8″ x 16″ |

| 8” Half CMU Blocks | 8″ x 8″ x 8″ |

| 10” Full CMU Blocks | 10″ x 8″ x 16″ |

| 10” Half CMU Blocks | 10″ x 8″ x 8″ |

| 12” Full CMU Blocks | 12″ x 8″ x 16″ |

| 12” Half CMU Blocks | 12″ x 8″ x 8″ |

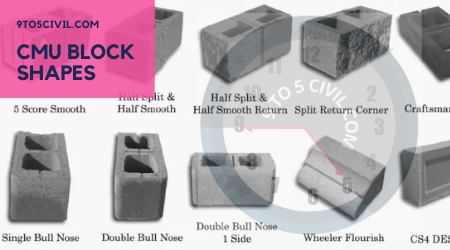

CMU Block Shapes

The composition of CMU blocks can be made of solid or hollow type with two or more cores. This feature reduces the density of the cross-sectional area of the concrete block. Which makes the CMU block is light in weight.

The use of hollow concrete blocks is an economical choice in building construction. Because they require less raw material, time, and energy than the production of solid blocks. The hollow concrete block is much easier to replace than the solid block.

Solid concrete blocks can be used for wall coping or for a variety of applications for building protection. Since hollow concrete blocks are less expensive than solid concrete blocks, they are the economically best solution for any project.

The following are some examples of different types of concrete blocks and their uses:

1. Stretcher Concrete Block

The stretcher concrete block is installed along the length of the wall on the bed. The stretcher concrete block is placed parallel to the face of the face wall.

2. Quion Corner Concrete Block

This type of concrete block is slightly larger than the surrounding block to give a strong look as a wall decoration. This type of concrete block is used as a “universal angle.”

3. “L” Corner Concrete Block

The “L” corner concrete block is used to give a smooth finish to the outer corners and gives a smooth look from three sides.

4. Bullnose Stretcher Concrete Block

Bullnose stretcher concrete block provides roundness in masonry work in the building.

Also Read : What Is a Concrete Wall Finish? | Types of Concrete Finishes

CMU Block Weight

The weight of CMU blocks varies according to the density of the concrete mix.

CMU blocks are mainly classified into three parts:

1) Lightweight CMU blocks = This type of concrete block usually weighs less than 102 lbs/ft.

2) Medium weight CMU blocks = This type of CMU block weighs between 109 lbs / ft 2 to 12 lbs / ft.

2) Normal weight CMU blocks = This type of CMU block weighs more than 18 lbs/ft.

CMU Retaining Wall Construction

Concrete block retaining wall construction includes phases including excavation, foundation soil preparation, base preparation, concrete block unit placement, and drainage system installation.

1. Excavation Work for CMU Block Retaining Walls

Excavation is done according to the layout of CMU retaining wall using proper excavation machines. It is excavated as required by the drawings mat. Then, the dressing and leveling of Excavation soil are done.

2. Soil Preparation for CMU Block Retaining walls

The excavation ground is compacted according to the drawings of the concrete block retaining wall design. The compacted soil should have at least 95% standard Proctor compaction test results. The base thickness of the retaining wall is kept at 100 to 150 mm.

3. CMU Block Placement in Retaining Wall

Concrete block units should be installed from properly certified grout material according to the design. The masonry work of the concrete block needs to be plumbed periodically.

During masonry work of CMU wall, the combined thickness of horizontal and vertical mortar in the block is kept as 10 mm.

If it is sometimes recommended to use 1 cement: 6 sand mixture for CMU Wall. Reinforcement is placed in masonry work to increase the strength of the retaining wall.

Also Read : What Is Interior Wall Finishes? | Type of wall finish

Advantages of CMU Wall

- Concrete masonry blocks are larger and lighter in weight than conventional bricks. Which is economically affordable for the construction of the entire CMU wall.

- The use of reinforcement in the walls of the CMU makes it stronger. So it helps to bear more weight without cracking as compared to brickwork.

- Strong walls made by reinforcement in CMU Wall have excessive resistance to heavy loads.

- The construction of the CMU Wall is suitable for an area with an extremely heterogeneous climate such as hurricanes and tornadoes.

- CMU wall has more durability than brickwork. With its proper interval, maintenance can last longer in the building.

- CMU Block can be used for many small landscape projects. The project includes outdoor seating, an outdoor bar, a flower bed, lots of outdoor furniture, etc.

- CMU Block protects against noise pollution as it has sound-absorbing properties.

Also Read : What Is Retaining Walls? | Uses of Retaining Wall | Types of Retaining Wall | Advantages of Retaining Wall

Disadvantages of CMU Wall

- Workers have to be trained for the production of CMU blocks. Because the production of CMU block requires experience and skills.

- Installing wiring and plumbing lines in CMU walls becomes difficult.

- During an earthquake, structures built using hollow concrete blocks without internal reinforcement are more likely to be damaged.

Like this post? Share it with your friends!

Suggested Read –

- What Is Construction Cost Estimate? | Type of Construction Cost Estimate | Advantage of Construction Cost Estimate | Disadvantage of Construction Cost Estimate

- What Is Residential Building? | Types of Residential Buildings | Site Selection for Residential Buildings

- Types of Beams in Constructions

- What Is Pier and Beam Foundation? | Advantages &Disadvantages of Pier and Beam Foundations | Difference Between Pier and Beam Foundation Vs Slab Foundation | Pier and Beam Foundation Cost

- What Are Curb and Gutter? | Difference Between Curb and Gutter | Types of Curb and Gutter | Construction of Curb and Gutter | Advantages of Curb and Gutter

What Are CMU Walls Used For?

A concrete masonry unit (CMU) is a standard size rectangular block used in building construction. CMU blocks are some of the most versatile building products available because of the wide variety of appearances that can be achieved using them.

What Is a Cmu Wall?

Concrete masonry units (CMU) and insulated concrete form (ICF) walls have several features in common: energy efficiency, durability, and good indoor environmental quality (IAQ). CMU Wall systems strive to create durable structures that are resistant to wind, moisture, fire, rot, and mold.

How Much Does a Cmu Wall Cost?

The national average materials cost to install a CMU block wall is $2.49 per square foot, with a range between $1.98 to $2.99. The total price for labor and materials per square foot is $14.44, coming in between $12.76 to $16.11.

What Cmu Means?

Concrete block is made from portland cement, aggregates, and water. It is also known as a concrete masonry unit (cmu).

How Much Is a CMU Block Wall Per Square Foot?

The national average materials cost to install a CMU block wall is $2.49 per square foot, with a range between $1.98 to $2.99. The total price for labor and materials per square foot is $14.44, coming in between $12.76 to $16.11.

How Thick Is Cmu Wall?

They are identified by their depth – i.e. The thickness of the wall they create. For instance, a 6″ CMU is nominally 6″ deep while a 10″ CMU is nominally 10″ deep.

How Much Does 12 Inch Concrete Block Cost?

Building and construction concrete block prices are $1 to $4 per block, depending on the size.

Are Cmu Walls Load Bearing?

The units are often used when masonry is to form a load-bearing wall or an interior partition between spaces within a building. Concrete masonry units can be manufactured in different sizes and with a variety of face textures.

Are Concrete Walls Cheaper Than Brick?

Currently, the market cost of brick masonry (per cubic meter) is rs. 8,500 whereas that of block masonry is rs. 1,500 cheaper. The cost of block walls per meter cube of hollow concrete masonry comes out to be 17.65 percent less than that of brick walls.

Skip to content

Skip to content