BrickWork

Brickwork is masonry usually produced by different layers of the brick using bricks and mortar. Typically, brickwork is laid on top of each other to form a brick wall-like structure.

Brickwork is a verticle element in building construction, which is usually constructed of bricks and mortar. Brickwork in buildings has been built for exterior walls, parapets, interior partitions, freestanding walls, retaining walls, etc.

In building construction, masonry is used to indicate the art of making a vertical wall out of stones or bricks. Brickwork is the most durable form of building construction.

Bricks made from clay, concrete, or calcium-silicate material were commonly used in brickwork. The size of bricks commonly used in building construction is 215mm (L) x 102.5mm (W) x 65mm (H).

Brickwork construction is done using brick and cement mortar. Horizontal (bed) vertical joints are usually kept 10 mm wide in brickwork construction.

Brick has been used in ancient culture to build buildings. The history of brickwork dates back to the Bronze Age. The circular brickwork of the ancient Dur-Kurigalzu Ziggurat in Iraq dates back to about 1400 BC. In addition, the ancient Mohenjo-Daro brickwork buildings in Pakistan are believed to be around 2600 BC.

Brickwork Construction

Brickwork construction is a very sustainable form of building construction. For its solid construction, it is built by placing bricks in a suitable bond in a mortar. Which safely transfers the load applied to it to the base. Various types of brick bond and mortar are used in brick masonry work as required.

The quality and durability of brickwork construction depend on things like a brick bond in brickwork and joints between bricks filled with suitable mortar etc. Be careful when mixing and placing mortar in the joints of brickwork. So that the bonding between the two bricks becomes strong.

In building construction bricks are usually separated from blocks by size. In the UK, for example, brick is defined as a unit with dimensions less than 337.5 mm × 225 mm × 112.5 mm. When a block is used as a unit with one or more dimensions.

The brickwork dimension is expressed as technical work in construction or technical documents. The brickwork coordination dimension gives the actual physical dimensions of the brick in building construction with a header face, a stretcher face, and a mortar on a bed.

The working dimension is the actual size of the manufactured brick. This is commonly referred to as the nominal size of the brick.

The size of the brick may be slightly different Dimensions due to shrinkage or deformation during the manufacturing process of the brick.

Types of Brick Work Construction

1. Brick Work in Mud

In this type of brickwork, construction mud is used as mortar. This mud mortar is used for bedding and filling of joints of Brickwork.

The thickness of the joint of the vertical and horizontal joints of mud mortar is usually kept at 12 mm. This type of brickwork is the cheapest type of masonry in construction

Masonry work can be done with mud mortar up to a maximum height of 4 meters

2. Brick Work in Cement

This type of brickwork construction is done by laying bricks in cement mortar instead of mud. Brickwork construction in cement mortar is done in first-class brickwork, second class brickwork, third class brickwork.

Classification of Brick Work

- First class brickwork

- Second class brickwork

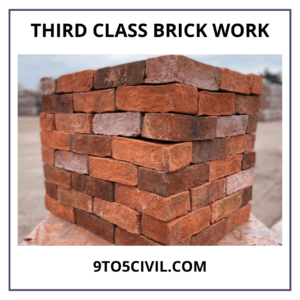

- Third class brickwork

1. First Class Brick Work

First-class bricks and cement mortar are used in first-class brickwork construction. This type of brickwork is done for the load-bearing walls of the building structure. In first-class brickwork, the ratio of cement and sand is kept from 1: 3 to 1: 6.

First-class bricks are usually the same color and two bricks are struck to produce a ringing sound.

First-class bricks have the same surface size and no cracks. First-class bricks do not absorb more than 1/6 of their weight of water. First-class bricks usually have a minimum crushing strength of 105 kg/cm².

2. Second Class Brick Work

Second-class bricks and cement mortar are used in second-class brickwork construction. These bricks have the same properties as first-class bricks. The use of such bricks should be avoided for load-bearing walls for two-story buildings. Second-class bricks usually have a minimum crushing strength of 70kg/cm².

3. Third Class Brick Work

This type of brickwork construction uses third-class bricks and cement mortar or mud mortar. Third-class bricks are not used in any government work. Third-class Brick is commonly used for temporary brickwork construction in the private sector.

Application of Brick work

- First-class brickwork has a standard shape, sharp edges, high durability, and strength. First-class brickwork is used in permanent structural construction buildings, dams, roads, bridge piers, etc.

- Brickwork construction is used for the construction of walls of any size, open brickwork construction, foundation brickwork, retaining walls, arches, and cornices.

- It can be used for informal walkway or door-to-door and paving in the walkway from the flower garden.

- Holes in brickwork construction can be used to make elegant planter/candle holders.

- Low-quality bricks or burnt bricks can be used as a base for foundation and overall for road metal works.

- High-quality bricks are used for decorative purposes in brickwork construction. Its use can provide a provision for architectural effects, and a suitable effect for use in textures, bonds, and joints.

- Sun-dried or non-burnt bricks are used only in the brickwork of temporary structures. This type of low-quality type brick should be avoided in building construction.

Advantage of Brick Work

- Brickwork is done as structural elements in various structures, as it is strong, hard, durable, abrasion and fire-resistant.

- This type of construction can easily make openings for doors and windows.

- All types of mortar can be used in brickwork construction. It can also use mud mortar for temporary buildings.

- Brickwork is done in buildings, bridges, arches, foundations, pavements (sidewalks, streets).

- Brickwork is used in building construction to achieve aesthetic finishing surfaces.

- Brickwork can be done to get different surface designs in different colors, sizes, and directions. In which bricks are used as an aesthetic material. brickwork construction is done in pavements, as facing bricks, and for architectural purposes.

- Brickwork can be used as a fire-resistant material in building construction.

- Demolishing the structure of brickwork is very easy, takes less time. Therefore, the demolition of brickwork is economical.

- The bricks used in brickwork are recycled.

- Brickwork construction is highly fire-resistant. Less environmental pollution is generated during the brick manufacturing process.

- This type of construction requires low maintenance costs.

- The high-quality binding strength of brickwork construction is very good. Brickwork is more durable in building construction.

- The compressive strength of brickwork is suitable for general construction.

- Since the shape and size of the bricks used for its construction are the same, they can be easily made for construction.

Disadvantages of Bricks Work

- Brickwork has low tensile strength.

- Brickwork construction requires experienced supervision.

- Brickwork is avoided in high seismic zones.

- Bricks have the property of absorbing a limited amount of water. Brickwork causes fluorescence when it is not exposed to air.

- Brickwork gives less architectural effects than rubble work.

- The strength of brickwork is less than that of stonework.

- Since the surface of the brickwork is rought, plastering is required. So the maintenance cost of brickwork is more.

Like this post? Share it with your friends!

Suggested Read –

- Type of Heavy Construction Equipment | Earth Moving Equipment | Material Handling Equipment

- The Standard Room Size & Location In House | Standard Room Size for Drawing or Living Room | Standard Size Of Bedroom | Standard Room Size for Kitchen | Standard Size Of Bathroom

- What Is CMU Wall? | Characteristics of CMU Block | CMU Block Dimensions | CMU Retaining Wall Construction | CMU Block Shapes | CMU Block Weight | Advantages & Disadvantages of CMU Walls |

- What Is Construction Cost Estimate? | Type of Construction Cost Estimate | Advantage of Construction Cost Estimate | Disadvantage of Construction Cost Estimate

- What Is Residential Building? | Types of Residential Buildings | Site Selection for Residential Buildings

How Often Should You Repoint Brickwork?

In a brick wall the brick must always be considered permanent and the mortar sacrificial. There should therefore be cycles of repointing at about 50 year intervals where the brick remains the permanent feature and the mortar is the element that is replaced.

What Happens If You Don’t Repoint Brickwork?

Unnecessary repointing, however carefully done, risks damage to the edges of bricks or stones, as well as the loss of valuable clues to a building’s construction and history. Unsatisfactory repointing can not only be visually disturbing but harmful to the actual fabric it is intended to protect.

What Is the Best Mix for Pointing Brickwork?

A typical mortar mix for Repointing purposes, for use in an area subject to normal weather conditions, would comprise 1 part Portland Cement, 1 part Lime and 5½ parts Sand,

Lime can be very beneficial in repointing mortars.

How Do You Price Brick Work?

Brick walls cost $10 to $45 per square foot depending on thickness and type. Stone walls run $25 to $80 per square foot depending on thickness and style. Cinder block walls cost $5 to $12 per square foot with veneers adding $5 to $12 per square foot.

What Do You Call Brick Work?

The word masonry refers both to the process of building things out of stone or brick and to the structures that result from this process.

What Is the Specification for 1st Class Brick Work?

If we want to make rich mortar, sand should be coarse or medium. For weak mortar, local fine sand may be used. Cement sand ratio of mortar should be 1:3 to 1:6 as specified. To get the required proportion, materials of mortar should be measured with the measuring box.

Skip to content

Skip to content