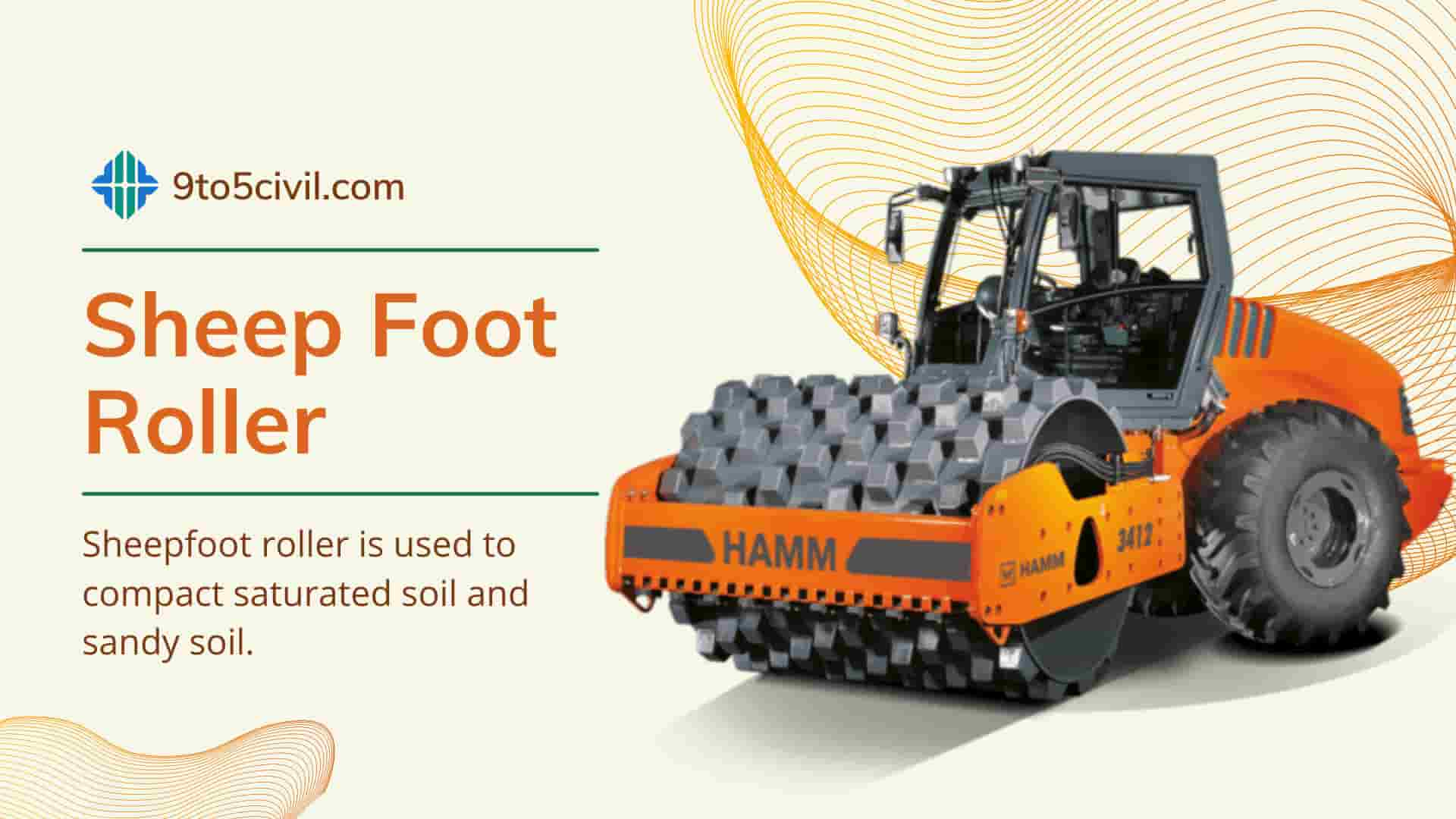

What Is a Sheepsfoot Roller?

The sheep foot roller is a static and vibration type roller. Sheep foot roller is a type of clay compaction machine. Sheepfoot roller is used to compact saturated soil and sandy soil. The weight can be increased by mounting a piece of land, water, and steel in a sheep foot roller. The sheep foot roller is specially designed for use.

The soil compaction is mounted in the sheep foot roller in the same way that a roller is fitted with a sheep foot. For proper compaction, the soil layer must be rotated 15 to 20 times in a foot roller. The compaction of the sheep foot roller depends on the size of the sheep foot, the weight of the roller, the number of lugs, and the foot contact with the ground.

Sheep foot roller is widely used in canal embankments. In addition, a sheep foot roller is used in dams, highways, canal beds, etc. A sheep foot roller is more suitable where there is a slope.

There are three types of sheep foot roller used,

- Ordinary sheep foot roller

- Convertable sheep foot roller

- Turn foot sheep foot roller

Also Read : What are Traps? | Specification of Plumbing Trap | 14 Types of Traps in Plumbing

Introduction to Sheep Foot Roller

The sheep foot roller has a 0.2 mt long sheep’s foot-like part on a cylindrical drum called lungs or feet. The lungs fitted in the sheep foot roller can be fitted in different shapes.

In a sheep foot roller, the lungs are arranged at a distance of 0.2 mt from each other cylindrical drums in a sheep foot roller weighing 1.5 to 10 tons.

A sheep foot roller has sheep foot pressure of 35 kg /cm2 The efficiency of a sheep foot roller depends on the sheep foot. Compaction is done slowly in sheep foot roller so that compaction of soil from sheet foot can be done properly. Compaction in a sheep foot roller also depends on the number of sheep feet attached to the drum.

Characteristics of Sheep Foot Roller

- Sheep foot roller is more effective where there are cohesive soils.

- In wet conditions, the sheep’s foot roller is not particularly useful.

- Ship feet of ship foot roller can be changed according to the ground.

- Ship foot roller compacts the ship foot from top to bottom.

- The compaction of the sheep foot roller depends on the size of the sheep foot, weight of the roller, number of lugs, and the foot contact with the ground.

- The depth of compaction of the sheep foot roller is 0.1 mt.

- Compaction can be done slowly with a sheep foot roller.

- The soil compaction is mounted in the sheep foot roller in the same way that a roller is fitted with a sheep foot.

Advantage of the Sheep Foot Roller

- The use of a sheep foot roller increases the bearing capacity of the soil.

- Rolling with sheep foot roller increases shear strength.

- Rolling with a sheep foot roller reduces permeability.

- Rolling with a sheep foot roller reduces land settlement.

- The advantage of the sheep foot roller is that it works in road construction. Sheep foot roller is very good for compacting plastic clay-like silty clay.

- The sheep foot roller is used as a vibration and static type roller and can be used for soil compaction with all fine clay and sand-gravel mixtures.

- Compression can be done to a greater depth than the other roller by the ship’s foot roller.

- Sheep foot roller is widely used in canal embankment. In addition, a sheep foot roller is used in dam, highway, canal bed, etc.

Disadvantages of Sheep Foot Roller

- Sheep foot roller is not used frequently in wet conditions.

- The sheep foot roller has to be rotated 15 to 20 times to compact the soil.

- Frequent rotation of the roller makes it expensive.

- Sheep foot roller makes the ground uneven. A smooth roller has to be used to level it from behind.

Also Read : What Is Gable Roof? | Design of Gable Roof | Types of Gable Roofs | Advantage & Disadvantage of Gable Roof

Application of Sheep Foot Roller

- This roller can be applied where there is more slope.

- Sheep foot roller is used for compaction of land to make railway and road.

- This roller gives good efficiency for compaction in high traffic routes.

-

Sheep foot can be changed in sheep foot roller as used in road.

- Ship foot rollers have different sizes of sheep foot available as per requirement.

Like this post? Share it with your friends!

Sheepsfoot rollers are used primarily for the compaction of cohesive, dense soils such as heavy or silty clays. They are not effective on loose or sandy soils due to the protrusions simply tilling the soil rather than compacting it. Evenness of compaction: The sheep foot roller may not create as flat of a surface as a smooth drum roller, due to its “feet.” Material: Sheepsfoot rollers are not effective on sandy or loose materials, because the “feet” of the padfoot drum tend to till, more than compact, them. Sheepsfoot rollers are used primarily for compaction of cohesive, dense soils such as heavy or silty clays. They are not effective on loose or sandy soils due to the protrusions simply tilling the soil rather than compacting it. A Padfoot roller, also referred to as a sheepsfoot roller, operates much like its smooth roller counterpart with one notable exception. It also implements manipulative force, or kneading, for compaction. The drum is covered with serrated protrusions that compress materials at greater depths. Characteristics of Sheepsfoot Roller: Just 8-12 % ground coverage under the lugs on the drum by the sheep foot rollers. A sheep foot roller compacting effort depends on the kneading and static weight. For cohesive soil, the sheep foot roller is mostly used. For sandy soils, such as heavy clays and silty clays except. The sheep foot roller can be applied as a vibration and static type roller for compaction of soil with a mixture of all fine-grained clay and sand-gravel. When from the bottom of each lift to the top should be compact as well as then the sheep foot roller is applied. The major difference between static and vibratory sheep foot rollers is their functions. Static rollers are used for compacting, while vibratory rollers are used for spreading and raking. What is the working principle of a Vibratory Sheepfoot Roller? The main function of a vibratory sheepfoot roller is to spread the material out as it compacts.What Is a Sheepsfoot Roller Used For?

What Are Disadvantages of Sheepsfoot Rollers?

What Is the Use of Sheepsfoot Roller?

Is a Sheepsfoot Roller Better Than a Smooth Roller?

What Are the Characteristics of Sheepsfoot Roller?

How to Use Sheep Foot Roller?

What Is the Difference Between Static and Vibratory Sheepfoot Rollers?

What Is the Efficiency of Sheepsfoot Rollers Compaction?

Skip to content

Skip to content