What Is a Slump Test?

The slump test is used to measure the workability of freshly made concrete. If concrete is made on the plant, a slump test is done on the plant itself. Equipment for slump tests can be easily carried on site. No specialist is required for the slump test. Therefore slump test is used more.

Concrete slump tester measures the consistency of a concrete batch to see how easily the concrete will flow. slump tester not only observes consistency between batches but also identifies defects in a mix, giving the operator a chance to amend the mix before it is poured on site.

The method of slump test is simple and easy. Therefore slump test is used more in fieldwork. According to IS code, the nominal aggregate size in fresh concrete in the slump test should not be more than 38 mm.

The slump test of each batch of concrete mixer can be prepared. During construction slump test is done to get uniform quality of concrete. The water-cement ratio can be improved with a slump test.

The slump test gives good results for the workability of concrete with a 25 to 125 mm slump.

Apparatus of Slump Test

1. Slump cone

The slump cone is mainly made of stainless steel. The diameter of the slump cone is as follows.

The slump cone has a top diameter of 10 cm and a bottom diameter of 20 cm. The height of the slump cone is kept at 30 cm.

2. Temping rod

The temping rod is made of stainless steel. The diameter of the temping rod is 16 mm.

3. Baseplate

The base plate is used for smooth surface and level.

What Does the Slump Test Measure

- First, take the slump cone and tamping rod to the place where the workability of the concrete is to be checked.

- The inside surface of the slump cone is then cleaned. Oil is applied to the inner surface of the slump cone so that the concrete can slide comfortably into the slump cone.

- The slump cone is then placed on a flat surface. The concrete is then filled layer-wise into the slump cone. Each level is pressed 25 times with a temping rod.

- The top layer is finished with a towel after the concrete is filled up in the slump cone. Now the slump cone is slowly lifted upwards, so the concrete slowly settles down.

- The distance between the surface of the slump cone and the surface of the concrete is called a slump.

Type of Slump

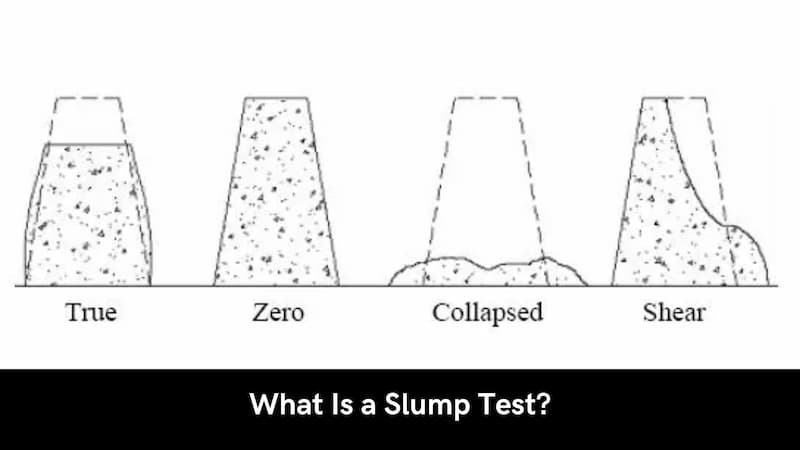

According to the workability of concrete, there are three types of slump, which are as follows.

1. True slump

A slump in which the variation is less, i.e., the same in all directions, is called a true slump.

2. Shear slump

If one-half of the concrete cone slides down, it is called a shear slump. The shear slump is measured as a difference in height between the height of the mold and the average value of subsidence.

If the sample shows a shear slump, the experiment shall be repeated. If in the repeated test also. The specimen shows a shear slump. The slump should be measured and recorded as a shear slump.

Shear slump indicates that the concrete is non-cohesive or harsh and shows the characteristic of segregation. this also indicates poor grading of aggregates.

3. Collapse slump

If the concrete spreads with the slump cone in elevation, the slump will collapse slump Says. The slump is usually 25 to 75 mm for low workability, 50 to 100 mm for medium workability, and 100 to 150 mm for high workability.

4. Zero slump

This type of slump has zero difference in the slump test when the concrete mix is very hard.

The workability of concrete from the same batch may vary.

Factors Affecting of Slump Test

The factors affecting of slump test are as follows,

- The ground should be level for the slump test. If the ground level is not level, then slump results are not correct.

- The slump test depends on the weather. As a result, it is not accurate in hot weather.

- Depending on the surface of the slump cone, if the surface inside the slump is rough, the result will not be true.

- Transport plays an important role in the slump test.

- Water cement ratio pan plays an important role in slump test.

Advantage of Slump Test

- The equipment for the slump test is light in weight.

- The method of slump test is easy.

- The equipment of the slump test can be easily transferred.

- The slump test can be done both in the field and in the laboratory.

- The result of the slump test is obtained fast.

- Equipment for the slump test is cheap.

- Only one man is required for the slump test.

- The slump test gives good results for the workability of concrete with a 25 to 125 mm slump.

- A slump test is done to maintain the consistency of material like aggregate, sand and admixture, etc.

Also Read : What Is Salt Finish Concrete? | Specification of Salt Finish Concrete | Process of Salt Finish Concrete

Disadvantage of Slump Test

- The slump test does not show workability for very wet and dry concrete.

- It does not give workability even in the concrete of hard mixing.

- The workability of the concrete in each batch varies.

- In this type of test, sufficient compaction should be done with the temping rod.

- Different results are obtained on the site and the plant.

- The surface of the base plate for the slump test should be free from vibration.

- Concrete should not be filled together in the slump test. It should be compacted about the level.

- Depending on the surface of the slump cone, if the surface inside the slump is rough, the result will not be true.

- The surface of the base plate for the slump test should be free from vibration.

Suggested Ranges of Workability of Concrete.

| No | Placing condition | Degree of workability | Slump(mm) |

| 1 | Pavement using paver, building concrete, shallow foundation | Very low | 75-80 |

| 2 | Mass concrete, beam, wall, column, strip footing, canal lining | Low | 25-75 |

| 3 | Heavily reinforced section in-wall, slab, column, beam | Medium | 50-100 |

| 4 | Slip formwork, pumped concrete | Medium | 75-100 |

| 5 | Trench fill, in situ piling | High | 100-150 |

| 6 | Tremie concrete | Very high | 100-175 |

- What Is Gypsum? | Types of Gypsum Products | Properties of Gypsum | Uses of Gypsum | Advantages & Disadvantages of Gypsum

- What Is Dam? | Parts of Dam | Types of Dams

- What Is Formwork? | Requirements of Good Formwork | Type of Formwork | Type of Shuttering | Advantages & Disadvantages of Formwork

- What Is Hydraulic Cement? | Hydraulic Cement Uses | Mixing of Hydraulic Cement | How to Apply Hydraulic Cement | Advantages & Disadvantages of Hydraulic Cement

- What Is Building Materials? | Type of building materials

- What Is a Roof Cricket and How Does It Work?

- What Is the Best Garage Door Insulation Kit?

- 10 Best Brands of Garage Door Openers

How to Measure Slump?

Place a straight edge, preferably the tamping rod, across the slump mold base, with one end suspended over the pile of concrete. Using a tape or ruler, measure the distance from the bottom of the straight edge to the displaced center of the slumped concrete. Record your results to the nearest 1/4 of an inch.

What Is Slump Test Used for?

A concrete slump test measures the consistency of a concrete batch to see how easily the concrete will flow. The test not only observes consistency between batches, but it also identifies defects in a mix, giving the operator a chance to amend the mix before it is poured on site.

What Is the Slump Test of Concrete?

The ‘slump’ of concrete refers to the consistency of fresh concrete before it sets – the higher the slump, the more fluid the concrete is. It’s a fairly confusing term for a complex-sounding process, but it really is quite simple when it all boils down.

What Does the Slump Test Measure?

The concrete slump test measures the consistency of fresh concrete before it sets. It is performed to check the workability of freshly made concrete.

What Is the Slump Test in Civil Engineering?

The concrete slump test measures the consistency of fresh concrete before it sets. It is performed to check the workability of freshly made concrete, and therefore the ease with which concrete flows. It can also be used as an indicator of an improperly mixed batch.

What Does Slump Test Test for Concrete?

A concrete slump test is used to determine the correct water content in a batch of concrete. “Slump” is the distance, measured in inches, the concrete settles after the slump cone is removed.

What Does the Slump Test Measure?

A concrete slump test measures the consistency of a concrete batch to see how easily the concrete will flow. The test not only observes consistency between batches, but also identifies defects in a mix, giving the operator a chance to amend the mix before it is poured on site.

Skip to content

Skip to content