Introduction of Gantry Girder Crane

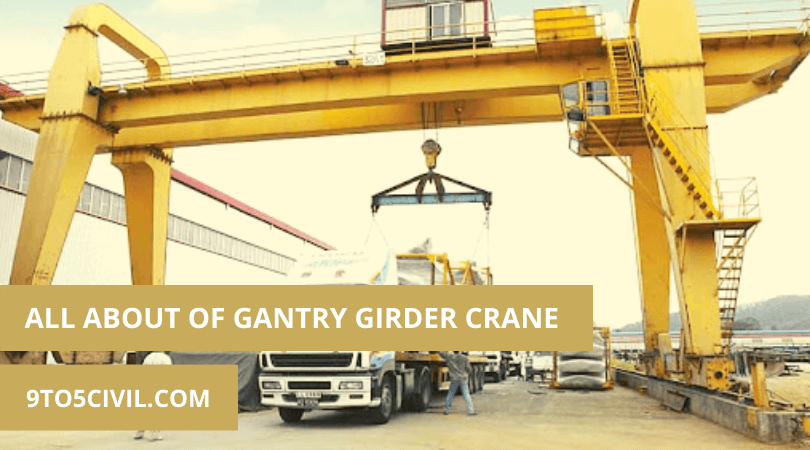

In the manufacturing plant, the heavy components of the machines are handled by an overhead traveling crane. The gantry girder is supported on the freestanding legs by single or double girder alignment in the crane, which proceeds by wheels or with a rail system.

In industrial heavy loads can be lifted by gantry girder crane for vertical and horizontal movement. In addition, a gantry girder crane is used to carry loads parallel to the length of the shed. This gantry Girder crane is electrically operated remotely.

What Is Gantry Girder Crane?

In gantry girders, the main girder supports the load coming through the travel wheels. The main girder extends from column to column. Sometimes a walkway can be made at the top of the girder as required and periodically inspected.

The Gantry Girder Crane is a very important and useful requirement for lifting and moving heavy loads in the shop area in workshops and factories. Supported gantry girders on the column carry the load through different elements. The hook-chain system in Gantry Girder is supported on the pulley.

The rail is fixed with strong clips to the top flange of the gantry girder. Gantry Girder cranes can be mounted as per slow speed type or fast speed type requirements.

Types of Gantry Girder Crane

The types of different gantry cranes used in construction are shown below

- Full Gantry Crane Systems

- Portable Gantry Crane System

- Adjustable Gantry Cranes

- Semi-Gantry Crane Systems

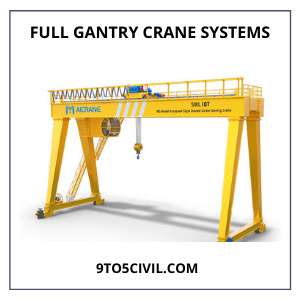

1. Full Gantry Crane Systems

- The full gantry crane is the most popular type of crane used. In which two strong legs ride on the rail. This type of Gantry Crane is mounted on the floor surface.

- They are usually able to work in a straight line in the workspace. The use of this type of crane allows motorized equipment such as trains and trucks to rotate and pass under the crane.

2. Portable Gantry Crane Systems

- Portable gantry cranes are small light-duty type gantry Girder Crane systems. Which usually runs on castor or rubber wheels. These wheels allow the user to handle various loads. It allows to move to different places.

- The portable Gantry Crane can be moved to another location to save more space in the shop when not in use. So this type of gantry Girder Crane can be stored anywhere in the shop.

3. Adjustable Gantry Cranes

- Adjustable gantry crane can be designed as required with height and span design. Adjustability gantry Girder Crane allows the user to change the height of the beam.

- Which gives more flexibility while transporting load in different areas of the shop.

Also Read : What Is Culvert? | Meterial for Culvert | Types of Culverts | Advantages of Culverts

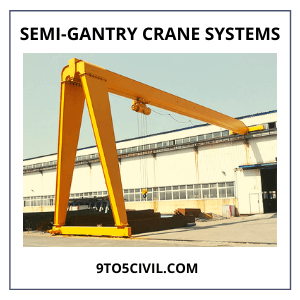

4. Semi-Gantry Crane Systems

- In this type of gantry girder crane, one foot rides on wheels and the other side of the crane is mounted on the runway system attached to the sidewall of the building column.

- The main advantage of this type of gantry girder crane is that it can save floor space/work space. Unlike a bridge crane, the setup of this crane does not require two runways.

Load on Gantry Girder Crane

- Gantry girders are unique for lifting loads on their own. Load due to longitudinal stress is applied to the beginning and closing of the gantry girder crane.

- It is necessary to evaluate the asymmetrical bending in the crab starting and closing operation due to lateral force.

- Due to the weight lifted by the gantry girder, an impact load is applied to it.

Often Gantry Girder is simply supported. In which stress is applied as follows,

- In Gantry Girder Crane, the reaction works towards the bottom.

- Longitudinal stress occurs in the Gantry Girder Crane when the crane starts or stops.

- Lateral stress is caused when the crab starts or stops working horizontally on the girder.

Types Of Load Acting On Gantry Girder Crane

1. Longitudinal Loads on Gantry Girder Crane

Longitudinal force is generated on the gantry girder when the crane is stopped after completion or when the crane is used for some work. In fact, the longitudinal force is generated in the first rail.

Especially fast working Gantry Girder Crane produces longitudinal force due to sudden application of brakes.

Gantry girder crane by longitudinal force provides friction resistance to the wheels during the locking process on the rail.

Gantry girders operate under bending moments due to loads of longitudinal force.

2. Vertical Loads on Gantry Girder Crane

The vertical load acting on the gantry girder crane is the result of the crane girder. The vertical load includes the self-weight of the granty girder crane and the crane capacity (the final load that can be lifted).

The reaction of the crane girder and the self-weight of the rail should also be taken into account for calculating the reaction. In addition, the maximum wheel load for lifting by the gantry girder crane is calculated.

3. Lateral Loads on Gantry Girder Crane

Lateral forces can induce the gantry girder on the crane,

(A). Force generated due to sudden crab stop and load generated during loadings of crab girders

Like longitudinal gantry girders, the lateral force transmits the friction resistance of the rail to the crab girder and from there to the crosshead girder, from there, as a point load through the main wheels of the gantry girder, to the top of the gantry girder or to the compression flange.

Maximum vertical bending moment and shear occur in the position of the main wheels, while maximum side bending and shear occur on the gantry girder.

(B). Lateral force generated during dragging weight on the shop floor by a crab in Gantry Girder

Useful for pulling weights on the shop floor by crane. If the load is large, it is usually mounted on crane rollers for dragging. Which usually protrudes sometimes on a wooden plank.

The lateral thrust becomes the subject of speculation after being pulled on the compressive flanges of the gantry girders.

In resisting forces on the gantry girder, the first main wheel is produced by walking on the gantry rails. And, secondly, the forces are given by the flanges of the main wheels coming over the gantry rails.

The lateral thrust acts in the plan of the center of gravity of the upper flange in the gantry girder. Because of this, it produces torque at the railway level.

Torque is neglected due to this small lever arm. Resistance to lateral thrust in the gantry girder is not caused by the lower or tensile flange.

Also Read :What are Traps? | Specification of Plumbing Trap | 14 Types of Traps in Plumbing

4. Impact Loads on Gantry Girder Crane

The stress is applied due to the load given on the gantry girder.This stress is caused by cranes operating quickly for work and the sudden use of brakes.

Steel frames can carry fast-moving cranes at work. It should be heavier than the steelwork of the crane, which supports slow-moving gantry girder cranes.

Quick-acting gantry girder Crane With electric overhead traveling (EOT), tension is immediately generated in the gantry girders. When in slow-moving hand cranes, the bending stress in the girder is gradually induced from zero to maximum values.

The appropriate factors represent the additional load as above. As per I.S: 875-1964, the additional load listed is considered for the gantry Girder. Structures in a gantry girder are subject to additional loads in addition to live loads.

Uses of Gantry Girder Cranes in Industry

1. Ship Building

Gantry Girder Crane is used in the shipbuilding industry for lifting heavy weights. It will help propel the ship using gantry cranes. So that parts of a large engine, such as an engine in a ship, can be installed in it. The crane helps in the movement of the ship while the building work is going on.

2. Warehouses

In warehouses, there is always a need for different types of heavy lifting items. Therefore, gantry cranes are found in almost all types of warehouses.

3. Automobile Industry

Small size gantry cranes are used in the automobile industry. Which can be used to lift engines in vehicles. In the automobile industry, engines vary according to the weight of different types of vehicles. The gantry girder will help in the entire lifting process in the automobile industry.

4. Manufacturing Units

Small-sized gantry girder cranes are used in manufacturing units. It is used to help move parts of the product element from one place to another. A 4-ton capacity gantry crane is commonly used in the manufacturing industry. Through which bulk goods can be transported at the same time.

Also Read :What Is a Beam Bridge? | Types of Beam Bridges | Advantage & Disadvantage of Beam Bridge

Like this post? Share it with your friends!

Suggested Read –

- What Is Well Foundation? | Shapes of Well Foundation | Component of Well Foundation |

- What Is Grillage Foundation? | Use of Grillage Foundation | Types of Grillage Foundation | Features of Grillage Foundation | Installation of the Grillage Foundation | Advantages & Disadvantages of Grillage Foundation

- What Is Standard Proctor Test? | Uses of Standard Proctor Test | Standard Proctor Compaction Test Apparatus | Procedure of Standard Proctor Test | Advantages & Disadvantages of Standard Proctor Test

- Coarse Aggregate Meaning | Origin of Aggregates | Requirements of Good Coarse Aggregates | Uses of Coarse Aggregates in Buildings Construction Works | Properties of Coarse Aggregates

- What Are Hollow Bricks? | Advantage of Hollow Brick | Disadvantage of Hollow Bricks | Sizes of Hollow Bricks | How to Make Hollow Bricks? | Hollow Bricks Properties | Uses of Hollow Bricks

Skip to content

Skip to content