What Is the Density of Building Material?

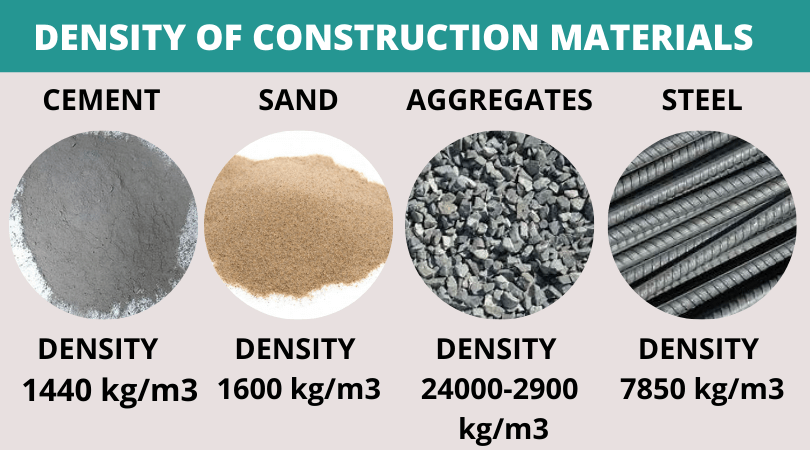

The Density Of Cement, Sand, And Aggregate generally plays a significant role in both production and operation in construction.

The density of any building material indicates the density of that material in a given area. The density of the material is defined as the mass per unit volume. Density represents essentially a measure of a particular substance.

It is a unique physical property for a particular object. The principle of density was discovered by Archimedes. To calculate density one has to understand its formula and its related units. Density is usually represented by the symbol અથવા or it can also be represented by the letter D.

ρ=mv.

Density Of Cement, Sand, And Aggregate

The density of building materials represents the mass of a unit volume of building materials. It is expressed in kg/m3 or lb/ft3 in units. Which shows the compactness of the building material.

Density is expressed as the unit weight of a substance. It is represented in the calculation as a symbol named (p). Density represents the degree of compactness of a material. This indicates that the material is more and less dense.

Density is defined as the unit weight of a mass.

p = m/V = 1/v, Where,

- p = density [kg/m3]

- m = mass [kg]

- V = volume [m3]

- v = specific volume [m3/kg].

Density of Cement

The density of cement generally plays a significant role in both production and operation in construction. The density of cement is important during the chemical process. Its production of raw minerals is placed in a large oven. Which produces “clinker”.

The final stage of cement production involves grinding (milling) and mixing. Which is known as cement in powder form. Cement specific density is a known influence of size in the development of cement hydration and strength.

A reduction in the average particle size in a given cement material produces a higher compressive strength. The density of cement should be combined with the design of the concrete mix to improve properties such as high starting strength.

Cement is widely used as a binder and adhesive material in building construction, superstructures, multi-story buildings, bridges, dams, and other civil structures. It acts as a bonding agent between aggregate and sand.

It is important to know the density of cement used as a binder material in concrete. In general, according to research, cement should have a density of 1440 kg/m3.

| Sr No | Cement Types | Density in KN/m3 | Density in Kg/m3 |

| 1 | Lime Mortar | 1600-1840 | 16-18 |

| 2 | Ordinary Cement | 1440 | 14.4 |

| 3 | PCC (Plain Cement Concrete) | 2400 | 24 |

Density of Sand

About 35% of the concrete in construction is made up of a mixture of sand. For the good quality and strength of concrete, it is necessary to know the properties of sand. Which helps in achieving the required maximum quality.

Usually, river sand is used for residential building construction. Natural sand has a bulk density of 1.71 kg/m3. While the specific gravity of natural sand is 7.5.

The density of sand has different densities in different conditions. As an example, if there is water in the sand, the density of the sand increases.

M-sand is commonly used in heavy construction work like gravity dams. m-sand is sand produced by crushing hard granite stone. The density of sand used as m-sand is 1.75 kg/m3.

The density of various sands are as follows,

- Loose sand in its dry form has a density of 1442 kg/m3.

- Dry sand that we get in natural form. It has a density of 1602 kg/m3. This type of sand is partially compacted by natural factors.

- The density of packed sand which is filled manually or mechanically is about 1682 kg/m3.

- The density of wet sand is about 1922 kg/m3. And wet-filled sand has a density of about 2082 kg/m3.

Aggregate Density

Aggregates include gravel, crushed stone, sand, slag, recycled concrete, and geosynthetic aggregates. Overall they are in natural, manufactured, or recycled form.

The density of aggregate depends on the size and size of the aggregate particles. Packing in particles of the same size can be done to a very limited extent.

Contains 60 to 80 per cent of the aggregate in concrete. Which produces compressive and bulk in concrete.

The aggregates are classified into two categories as follows:

- Fine aggregate

- Coarse aggregate

Fine aggregates usually consist of sand or crushed stone. Which is less than 4.75 mm in size. The coarse aggregate is usually between 4.75 mm and 37.5 mm.

The use of mixed fines and coarse aggregates reduces the chance of void in concrete. The quality of concrete can be improved with the correct mix of aggregate.

Bulk Density of Aggregate

The bulk density of aggregates indicates the number of aggregates. By which it is necessary to fill the container of unit volume by dividing it into batches on the basis of volume.

If larger particles than small particles of aggregate occupy more space. So its bulk density is low. Thus, the particle shape of aggregate greatly affects the density of aggregate.

The bulk density of aggregate indicates the amount of aggregate. Which is used to fill a specific unit quantity into a container.

Bulk Density = Mass/volume

The approximate bulk density of aggregate in normal-weight concrete is about 1200-1750 kg/m3. The standard testing method for determining the bulk density of units is referred to in ASTM C29.

Relative Density of Aggregate

The relative density (specific gravity) of aggregate is the ratio of its mass to the mass of water contained in it.

Relative Density = Mass of the Aggregate/Mass of equal volume of water.

Most aggregates have a relative density of 2400-2900 kg/m3. The relative density of the aggregate can be determined on the basis of the saturated surface-dry method (SSD).

Density of Fly ash

The density of fly ash is usually between 300 and 500 m2 / kg, although some fly ash has a density of less than 200 m2 / kg and some have fly ash with a surface area as high as 700 m2 / kg. The bulk density of fly ash can range from 540 to 860 kg / m3. When the bulk density of the compacted fly ash is a

1120 to 1500 kg / m3 (70 to 94 lb / ft3).

Fly ash consists primarily of silica, as well as small components such as alumina, iron, and calcium, as well as magnesium, sulfur, sodium, potassium, and carbon.

Density of Fumed Silica

Silica fume is also known as micro silica Silica fume is a by-product of an electric arc furnace. Which is used as a pozzolanic material. The bulk density of silica fume can be between 130 and 430 kg / m3 (8 to 27 lb / ft3).

Silica fume is available in powder form and in liquid form. Silica fume is used in between 5% and 10% of the mass of total cementitious material. It is used in high permeability degrees and high strength concrete.

Density of Building Materials As Per IS 875 Part-1

| Sr No | Construction Materials | Density (Kg/m3) | Density (lb/Ft3) | Density (Kn/m3) |

| 1 | Concrete (PCC) | 2400 | 149.8 | 24 |

| 2 | Concrete (RCC) | 2500 | 156 | 25 |

| 3 | Cement | 1440 | 89.8 | 14.4 |

| 4 | Rapid Hardening Cement | 1280 | 79.87 | 12.8 |

| 5 | Sludge | 2100 | 131 | 21 |

| 6 | Sandstone | 2000 | 124.8 | 20 |

| 7 | Ordinary Cement | 1440 | 89.87 | 14.4 |

| 8 | African Mahogany | 495-850 | 31-53 | 4.95-8.5 |

| 9 | Willow Wood | 420 | 26.2 | 4.2 |

| 10 | Aspen | 420 | 26.2 | 4.2 |

| 11 | Ferry | 170 | 10.6 | 1.7 |

| 12 | Pine | 370-530 | 23-33 | 3.7-5.3 |

| 13 | Bamboo | 300-400 | 18.7-25 | 3.0-4.0 |

| 14 | Cedar | 380 | 23.7 | 3.8 |

| 15 | Saline Water | 1025 | 63.96 | 10.25 |

| 16 | Water | 1000 | 63.43 | 10 |

| 17 | African mahogany | 495-850 | 31-35 | 4.95-8.5 |

| 18 | Honduras mahogany | 545 | 34 | 5.45 |

| 19 | American redwood | 450 | 28 | 4.5 |

| 20 | European redwood | 510 | 31.8 | 5.1 |

| 21 | Fir (staka) | 450 | 28 | 4.5 |

| 22 | Fir(Canadian) | 450 | 28 | 4.5 |

| 23 | Aphromosia | 7.05 | ||

| 24 | apple | 660-830 | 1.2-51.8 | 6.6-8.3 |

| 25 | Gray (black) | 540 | 33.7 | 5.4 |

| 26 | Gray (white) | 670 | 41.8 | 6.7 |

| 27 | Carvalho | 590-930 | 36.8-58 | 5.9-9.30 |

| 28 | Teak | 630 | 9.3 | 6.3 |

| 29 | Sycanmore | 590 | 36.8 | 5.9 |

| 30 | Iroko | 655 | 40.9 | 6.55 |

| 31 | Larch | 590 | 36.8 | 5.9 |

| 32 | Maple | 755 | 47.1 | 7.55 |

| 33 | Birch | 670 | 41.8 | 6.7 |

| 34 | Ebony | 960-1120 | 59.9-69.9 | 9.6-11.20 |

| 35 | Elm | 600-815 | 37.4-50.8 | 6.0-8.15 |

| 36 | Lignum vitae | 1280-1370 | 79.9-85.5 | 12.80-13.70 |

| 37 | Sandy Soil | 1800 | 112.3 | 18 |

| 38 | Clay Soil | 1900 | 118.6 | 19 |

| 39 | Gravel soil | 2000 | 124.6 | 20 |

| 40 | Chalk | 2100 | 131 | 21 |

| 41 | Shale | 2500 | 156 | 25 |

| 42 | Sedimentary rocks | 2600 | 162.3 | 26 |

| 43 | Metamorphic rocks | 2700 | 168.5 | 27 |

| 44 | Igneous (felsic) rock | 2700 | 168.8 | 27 |

| 45 | Igneous(mafic) rock | 3000 | 182.7 | 30 |

| 46 | Bricks | 1500-1800 | 93.6-112.3 | 15-18 |

| 47 | Steel | 7850 | 490 | 78.5 |

| 48 | Stainless steel | 7480-8000 | 766.9-499.4 | 74.8-80 |

| 49 | Cement mortar | 2080 | 129.8 | 20.8 |

| 50 | Lime mortar | 1760 | 109.8 | 17.6 |

| 51 | Asphalt | 721 | 45 | 7.21 |

| 52 | Lima | 640 | 39.9 | 6.4 |

| 53 | Aluminium | 2739 | 170.9 | 23.79 |

| 54 | Magnesium | 1783 | 108.3 | 17.34 |

| 55 | Cobalt | 8746 | 545.9 | 87.46 |

| 56 | Nickel | 8908 | 556.1 | 89.08 |

| 57 | Cast iron | 7208 | 449.9 | 72.08 |

| 58 | Copper | 8940 | 558.1 | 89.4 |

| 59 | Zinc | 7135 | 445.4 | 71.35 |

| 60 | Tin | 7280 | 454.4 | 71.35 |

| 61 | Lead | 1134 | 707.9 | 113.4 |

| 62 | Iron | 7850 | 490 | 78.5 |

| 63 | Glass | 2850 | 161 | 25.8 |

| 64 | Bitumen | 1040 | 64.89 | 10.4 |

| 65 | Brick Dust | 1010 | 63.024 | 10.1 |

| 66 | Sand (Wet) | 1760-2000 | 109.82-124.80 | 17.6-20.00 |

| 67 | Stone Ballast | 1720 | 107.33 | 17.2 |

| 68 | Stone Chips | 1600-1920 | 99.84-119.81 | 16.00-19.20 |

| 69 | Fire Bricks | 2400 | 149.76 | 24 |

| 70 | Granite Stone | 2400-2690 | 149.76-167.85 | 24-26.90 |

| 71 | Gypsum Mortar | 1200 | 74.88 | 12 |

| 72 | Gypsum Powder | 1410-1760 | 87.98-109.82 | 14.10-17.60 |

| 73 | Ice | 920 | 57.41 | 9.2 |

| 74 | Plane Cement Concrete | 2400 | 149.8 | 24 |

| 75 | RCC | 2500 | 149.8 | 24 |

| 76 | Rubber | 1300 | 81.12 | 13 |

| 77 | Sal Wood | 865 | 53.98 | 8.65 |

| 78 | Sand (Dry) | 1540-1600 | 96.09-99.84 | 15.40-16 |

| 79 | Clay Soil | 1900 | 118.56 | 19 |

| 80 | Earth (Dry) | 1410-1840 | 87.98-114.82 | 14.10-18.40 |

| 81 | Earth (Moist) | 1600-2000 | 99.84-124.8 | 16.00-20.00 |

Density of Steel

The density of steel varies depending on the alloying components in it but is usually between 7,750 and 8,050 kg/m3.

| Sr.No. | Dia of Bar | Density of Steel as per Dia (Kg/m2) |

| 1 | 8 | 0.395 |

| 2 | 10 | 0.619 |

| 3 | 12 | 0.888 |

| 4 | 16 | 1.58 |

| 5 | 20 | 2.469 |

| 6 | 25 | 1.388 |

| 7 | 28 | 4.839 |

| 8 | 32 | 6.32 |

| 9 | 40 | 9.87 |

Density of RCC

Reinforced cement concrete (RCC) increases the tensile strength of concrete. Concrete resists well against compression. Concrete is unable to resist stress. Reinforcement is placed in concrete due to weak tension stress.

The density of RCC is taken into account to get sufficient strength as per the requirement of concrete. Density is measured keeping in mind the quality of the material. Due to which RCC needs to be compacted.

According to the prescribed IS code, the density of RCC is 2400 kg/m3.

Density of PCC

Factors affecting the density of concrete include the density of aggregate, air content, water, and cement content. Pcc has to be done in a wide area.

The density of Portland cement concrete (PCC) in the foundation is 2400 kg/m3.

Density of Fine Aggregate

Density of sand (fine aggregate) is ranging between 1450 – 2082 kg/m3 depending on different condition like wet, dry, loose, dry-packed, and wet packed.

Density of Coarse Aggregate

Most of the aggregates possess a relative density within 2.4 – 2.9 with a similar particle density about 2400-2900 Kg/m3 (150-181 lb/ft3).

What Is Cement Density?

2.8 g/cm³ (gram per cubic centimetre)

Density of Cement in kg/m3

As I said, earlier density is the material’s mass per unit volume. Since we measure mass in kg or lb and volume in litre or cubic meter or cubic feet, hence density is stated in Kg/m3 or lb/ft3. The density of OPC cement is = 1440 Kg/m3.

Density of Sand

Density of sand (fine aggregate) is ranging between 1450 – 2082 kg/m3 depending on different condition like wet, dry, loose, dry-packed, and wet packed.

Bulk Density of Aggregate

The bulk density or unit weight of an aggregate is the mass or weight of the aggregate that required to fill a container of a specified unit volume. Key Features: The approximate bulk density of aggregate that is commonly used in normal-weight concrete is between 1200-1750 kg/m3 (75-110 lb/ft3).

Bulk Density of Sand

The approximate bulk density of sand that is commonly used in normal-weight concrete is between 1520-1680 kg/m3 (95-105 lb/ft3)

Density of Crushed Sand

Crush sand used as a partial replacement of fine sand in the construction line and the density of M /crush sand is 1750 kg/m3, specific gravity and fineness of modulus are found to be 2.73 and 4.66 respectively.

Coarse Aggregate Density

Most of the aggregates possess a relative density within 2.4 – 2.9 with a similar particle density of about 2400-2900 Kg/m3 (150-181 lb/ft3).

Density of Concrete

The density of concrete varies but is around 2,400 kilograms per cubic meter (150 lb/cu ft). Reinforced concrete is the most common form of concrete.

Density of Concrete Kn/m3

| Material | Mass density (kg/m3) | Weight density (kN/m3) |

|---|---|---|

| Concrete (unreinforced) | 2300 kg/m3 | 23 kN/m3 |

| Brickwork | 1900 kg/m3 | 19 kN/m3 |

| Timber (Softwood) | 600 to 800 kg/m3 | 6 to 8 kN/m3 |

| Timber (Hardwood) | 800 to 1100 kg/m3 | 8 to 11 kN/m3 |

Density of Concrete g/cm3

Concrete is to a large extent dependent on its density which in the case of ordinary concrete generally ranges between 2.2 and 2.4 g/cm3. Heavy or high-density aggregates are used to increase the density of concrete.

Density of Concrete in Kg/ft3

| Material | Density (lb/Ft3) | Density (Kg/m3) |

|---|---|---|

| Concrete, Gravel | 150 lb/ft3 | 2,400 kg/m3 |

| Crushed Stone | 100 lb/ft3 | 1,600 kg/m3 |

| Earth, loam dry excavated | 90 lb/ft3 | 1,440 kg/m3 |

| Earth, packed | 95 lb/ft3 | 1,520 kg/m3 |

Density of Concrete in Kg/m3

As for concrete itself, the density of concrete of normal weight is about 2,400 kg per cubic meter or 145 lbs.

Density of Concrete Per Cubic Foot

As for concrete itself, the density of concrete of normal weight is about 2,400 kg per cubic meter or 145 lbs. per cubic foot.

Density Calculation Steps

The five steps for determining density can be expressed in simple form as follows: measure the mass of the container, measure the volume of the liquid, measure the combined mass of the liquid and the container, determine the mass of the liquid alone, and divide the mass by the volume.

Fine Sand Density

In Imperial or US customary measurement system, the density is equal to 124.79 pounds per cubic foot [lb/ft³], or 1.16 ounces per cubic inch [oz/inch³].

Density of M sand

M– Sand was used as a partial replacement of fine aggregate. The bulk density of manufactured sand was 1860 kg/m³, specific gravity and fineness modulus was found to be 2.56 and 3.10 respectively.

Density of River Sand in kg/m³

Sand, dry weighs 1.631 gram per cubic centimeter or 1 631 kilograms per cubic meter, i.e. density of sand, dry is equal to 1 631 kg/m³.

What is Density of Fine Aggregate?

Density of sand (fine aggregate) is ranging between 1450 – 2082 kg/m3 depending on different condition like wet, dry, loose, dry-packed, and wet packed.

What is Density of Cement?

What is Bulk Density of Aggregate?

The bulk density or unit weight of an aggregate is defined as the mass of the aggregate per unit volume. it is expressed in kg/liter.

What is the value of Coarse Aggregate Density?

Most of the aggregates possess a relative density within 2.4 – 2.9 with a similar particle density about 2400-2900 Kg/m3 (150-181 lb/ft3).

How to calculate density of concrete?

- Weigh the container with the concrete (2) – record value to the nearest tenth of a pound.

- Subtract the empty container weight from the full container weight (2) – (1) = weight of concrete (3)

- Divide the weight of concrete by the known volume (3) / (4) = density, or fresh unit weight.

What is Density of Concrete?

The density of concrete varies but is around 2,400 kilograms per cubic meter (150 lb/cu ft).

Does fly ash increase density?

With the increasing percentage of fly ash (filler aggregate), the placing of fly ash density would increase until it reached an optimum point (point 3). The value of placing density would decrease beyond this point.

Like this post? Share it with your friends!

Suggested Read –

- 5 Best Sealer for Granite Countertops

- 5 Best Battery for Sump Pump Backup 2023

- What Size Staples for Insulation?

- What Is the Best Brand of Carpet to Buy?

- What Is the Best Insulation for an Attic?

- What Are The Best Gutters For Heavy Rain?

- What Is the Best Sealant for Leaking Pipes?

Skip to content

Skip to content

“Natural sand has a bulk density of 1.71 kg/m3”

You’re off by a factor of 1000. The table near the end has a correct range.

The correct bulk density of natural sand is approximately 1,710 kg/m³. This value may vary depending on factors such as the composition and moisture content of the sand.

Thank you for bringing this to my attention, and I hope this correction is helpful.

The bulk density of natural sand is indeed in the range of 1.4 to 1.6 metric tonnes per cubic meter (or 1400 to 1600 kg/m³).