Introduction of Formwork

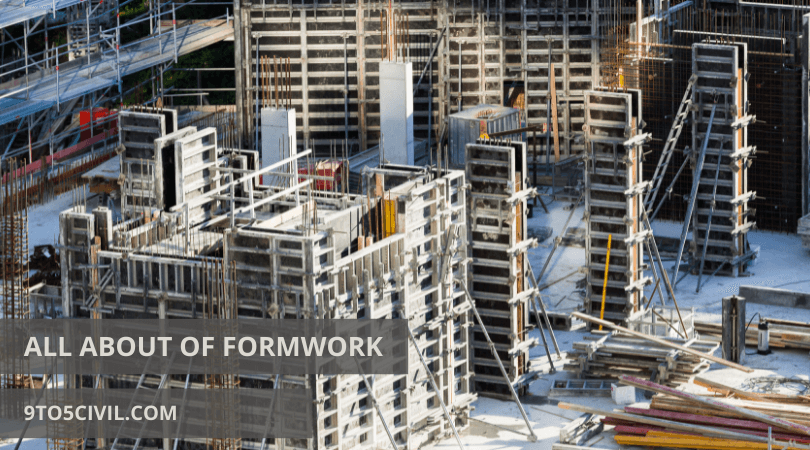

Formwork is used as a temporary construction. It is used to give the concrete the right shape at the prescribed height. Formwork is erected on a temporary basis to support the concrete until it reaches full strength.

Formwork is removed when the concrete has reached its required strength. The shape of the interior face can be obtained according to the concrete proper design using formwork.

Formwork has been used in construction for hundreds and thousands of years. With the help of formwork, structures of all sizes and shapes can be created.

What Is Formwork?

Formwork (shuttering) is a temporary construction designed to provide temporary support as a mold of fresh concrete. It is capable of pouring concrete into this temporary structure corresponding to the building, compacting it, and casting it to the desired shape. Formwork is removed when concrete has gained its proper strength.

Formwork made of timber or steel is commonly used in construction. Which are selected for the required finishing of Concrete for the building. Formwork and related falsework should be able to support the weight of wet concrete without distorting its work.

Formwork made from different materials for construction is as follows: such as steel formwork, aluminum formwork, timber formwork, plywood formwork, fabric formwork, plastic formwork.

Forming the formwork requires proper fixing of the various components with each other which takes more time. The cost of this temporary formwork can be about 20 to 25% of the cost of the constitution. This temporary formwork is designed for economic costs. The operation of removing formwork can generally be defined as stripping.

Formwork is a much-needed temporary structure in the construction industry. This formwork is sometimes used as a temporary or permanent form. In which concreting is done to mold the concrete. It acquires sufficient strength over time.

Requirements of Good Formwork

- The formwork should be able to carry a variety of dead and living loads. Different types of loads on formwork include self-weighting during and after casting of concrete, the weight of reinforcement, the weight of wet concrete, a load of workers and any other load, etc.

- Fixing should be done tightly enough to prevent leakage from the joints in the formwork.

- Formwork should be light in weight. So that it can be easily transported.

- The formwork should be such that various parts can be opened in the desired order without damaging the concrete.

- The material for the formwork should be inexpensive, easily accessible.

- The material of the formwork should be reusable.

- The surface of the formwork should be plain and smooth, plus it can be properly constructed on the desired line and level.

- The material of the formwork should not be bent or deformed in different weather conditions.

Also Read : What Is False Work? | Types of Falsework | Causes of Falsework Failures

Type of Formwork

- Timber Formwork

- Steel Formwork

- Aluminum Formwork

- Plywood Formwork

- Plastics Formwork

- Fabric Formwork

1. Timber Formwork

Timber formwork is the common type of formwork used in construction. Timber has been widely used in construction since ancient times.

The wood used for wood formwork is light in weight. So it can be used easily. The surface of the wood that comes in contact with the concrete should be smooth.

Timber formwork depends on the size of each part of the building.

Advantages of Timber Formwork

- The purchase price of wood formwork is lower than other formwork.

- Timber formwork can be easily cut for any shape, size, and height for building.

- Wooden formwork can be easily used for construction.

- Timber formwork can be easily used for small houses. This formwork is cheaper to use for a small house.

- Timber formwork is light in weight and can be easily transported.

- Wood formwork can be used in other ways when not to be used for temporary construction.

Disadvantage of Timber Formwork

- Timber formwork can only be used in a short span.

- Since wood in wood formwork is natural and cellular, the wood shrinks, swells, twists, cracks due to changes in climatic conditions.

- The maintenance cost of timber formwork is higher than other formwork.

2. Steel Formwork

Steel formwork has become one of the more popular because of its long-term strength, durability and repeated use. Using steel formwork is expensive for small work. But its use can be the right choice for large projects.

Steel shuttering gives a smoother surface for concrete than wood formwork. Its use is especially suitable for curved constructions. These curved constructions include tanks, columns, chimneys, gutters, tunnels and retaining walls, etc.

Advantages of Steel Formwork

- Steel formwork has a strong, durable, and long life compared to other formwork.

- Steel formwork provides a smoother finish to concrete surfaces than timber formwork.

- The steel formwork forms a completely waterproof type. The use of steel formwork reduces the effect of honeycombing on the concrete surface.

- The various elements of steel formwork can be fixed more easily and this formwork can be easily removed.

- Steel formwork is durable. so it does not shrink. So it can be used frequently.

Disadvantages of Steel Formwork

- It is too expensive to use steel formwork.

- The element of steel formwork is heavy in weight. Devices are needed for lifting large structure formwork.

- Corrosion occurs when the steel formwork is in constant contact with water. Because of this its maintenance is expensive.

- The size and shape of different elements in steel formwork are limited.

3. Aluminum Formwork

The aluminum formwork system for the structure of concrete is probably the most modern construction system. Aluminum Formwork can be used equally well in both upper and lower constructions.

Aluminum formwork is typically used to allow faster construction for multiple-unit projects. Aluminum formwork can be used for various elements ranging from straight panels to more complex structures such as open windows, stairs, etc.

The design of aluminum formwork can be done by unskilled labor. Each component is light enough to handle. This type of formwork reduces the need for heavy training equipment.

Advantage of Aluminum Formwork

- The complete concrete structure of the building can be made by the complete system of Aluminum Formwork.

- Aluminum Formwork is designed to suit the project requirements and its panels are made.

- Aluminum formwork reduces time and effort in building construction.

- This type of formwork can be used to obtain a clean and smooth surface of the concrete.

- The use of aluminum formwork is also effective if a significant number of symmetrical buildings are to be constructed.

Disadvantages of Aluminum Formwork

- Aluminum formwork is initially more expensive than other formwork.

- Aluminum formwork is expensive for single building use.

- Initially, it takes a long time to get started as it is difficult to connect its sections.

- For this type of formwork, the various elements have to be configured and maintained properly.

4. Plywood Formwork

Plywood is a product made of wood. Which is used for formwork in construction. It is formed from a thin layer of wood in different layers.

Plywood formwork is able to provide lightweight, durable and high-quality concrete cast surfaces.

The use of plywood formwork is increasing in construction. Which are specially designed to face panels. Plywood formwork provides a smoother finish than most ordinary wood formwork.

Therefore the use of plywood formwork can reduce the final cost in construction.

Plywood boards are commonly found in the market in thicknesses ranging from 7 mm to 32 mm.

1220 x 2440 size and 18 mm thick boards are commonly used for plywood formwork. Plywood formwork can also be made for curved structures.

Advantages of Plywood Formwork

- The plywood used for plywood formwork can be easily cut to the required size.

- Plywood formwork is stronger, more durable, and lighter in weight than other formwork.

- The surface of the concrete from plywood formwork provides a smooth finish.

- Very large size plywood sheets are available in the market for plywood formwork so that the construction of formwork can be made quick and easy.

- Plywood can also be used for curved formwork.

- While plywood formwork can be used one to two times more than timber formwork.

Disadvantages of Plywood Formwork

- Plywood formwork is more expensive than wood formwork.

- To maintain the weight of concrete in plywood formwork requires extra support by arranging wall plates close to thin plywood sheets.

Also Read : What Is a Beam Bridge? | Types of Beam Bridges | Advantage & Disadvantage of Beam Bridge

5. Plastics Formwork

Plastic formwork can be used for the construction of concrete columns, pillars, walls, and foundations.

Plastic formwork allows for easy construction of walls of any thickness and height. Wall panels are made of ABS plastic material. This type of plastic formwork is light in weight making it easy to transport.

The use of plsatic formwork allows construction in a variety of water and weather conditions.

Advantages of Plastic Formwork

- Plastic formwork is light in weight and easy to handle.

- Formwork can be prepared quickly for complex-shaped structures.

- Plastic formwork has good resistance to water.

- The damaged plastic sheet can be used to make new sheets.

- Good quality plastic formwork can be reused frequently

Disadvantages of Plastic Formwork

- This type of formwork makes the plastic weaker against heat.

- Plastic formwork is a more expensive material than other formwork.

Also Read : What Is Gable Roof? | Design of Gable Roof | Types of Gable Roofs | Advantage & Disadvantage of Gable Roof

6. Fabric Formwork

Fabric formwork is a modern technology used for construction. Able to mold fabric into any shape.

Which is more famous for designing in any shape and for architectural purposes.

Advantages of Fabric Formwork

- The weight of fabric formwork is much less than any other formwork.

- Fabric formwork is economically effective.

- Fabric formwork can be easily used for any complex shape.

- The fabric formwork is of the waterproof type.

- Fabric formwork does not change the properties of concrete.

- This type of formwork can be easily removed after the concrete has hardened.

Disadvantages of Fabric Formwork

Installation requires skilled workers. Because creating the perfect and necessary complex shapes requires the right skill.

Like this post? Share it with your friends!

Suggested Read –

- What Is Hydraulic Cement? | Hydraulic Cement Uses | Mixing of Hydraulic Cement | How to Apply Hydraulic Cement | Advantages & Disadvantages of Hydraulic Cement

- What Is Building Materials? | Type of building materials

- What Is Foundation Repair? | Signs of Foundation Problem | House Foundation Repair Methods

- What Is Skillion Roof? | Types of Skillion Roof | Uses of Skillion Roof | Advantages & Disadvantages of Skillion Roof | Cost of Skillion Roof

- What Is Road Pavement? | Function of Road Pavement | Ideal Road Pavement Requirement | Difference Between Rigid Pavement and Flexible Pavement

Skip to content

Skip to content