What Is Chain Surveying?

Chain surveys are the branch for linear measurements of surveys. In which a chain is used for linear measurement in a field. Chain surveying is useful for surveying small areas with simple details. Chain surveying in a fairly flat area gives measurement with precision.

Chain surveying has been used in England and other countries for centuries. The Surveyor’s Chain was first mentioned in 1579, and the Surveyor’s Chain Use In 1620, the polymath Edmund Gunter developed a method of surveying the land using a 66-foot-long chain with 100 links.

It is the simplest method of taking a linear measurement in a detailed survey. In this method, the length of the lines of the marked places on the field is measured, while the other details are measured by offset.

Principle of Chain Surveying

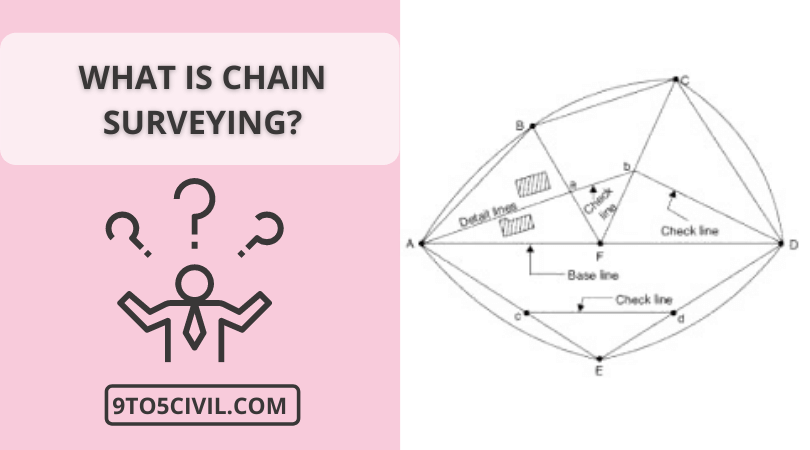

The main principle of a chain survey is surveying by triangulation. In chain surveying, the area to be surveyed is divided into several smaller triangles, and it is well divided into these triangles.

In surveying the chain, the triangle sides are measured on the field directly above the location by the survey chain. And no angular measurement will be taken into it. It should be noted that no angular measurement is required to form a triangle.

Instruments Used in Chain Surveying

- Chain or Tape.

- Arrows (Arrows in Surveying).

- Pegs.

- Offset Rods.

- Range Rod (Ranging Rod).

- Offset Rods.

- Hammer.

Chain

The chain is made by connecting 100 pieces of galvanized steel wire 4 mm in diameter. The ends of these pieces are bent to connect with each other. The pieces are then connected to each other with the help of three oval rings, which makes the chain flexible.

Two brass handles are connected at both ends of the chain. Tallies are provided at every 10 or 25 links for long-distance counting.

Arrows

An arrow is used to accurately mark the end of a chain and calculate the length of an entire chain when measuring length on a field.

The arrow used for surveying is made of good quality soft steel wire of 4 mm diameter. The upper edge of the arrow is 5 cm. They are rounded together. While the lower end is pointed. The height of the arrow used in surveying is 400mm.

Pegs

The use of wooden pegs is fixed to mark the position of the survey point or the endpoints of the survey line on the ground. Pegs should be made of good quality solid wood.

Its head is square, and the end is sharp. The size of the top head of pegs is 2.5 cm. X 2.5 cm. Or 3 cm. X 3 cm and length 15 cm.

The pegs are fixed to the ground by a hammer so that the head of the wooden pegs is 4 cm above the ground. A nail fix is done on it to indicate the exact location of the survey station.

Ranging Rods

The ranging rod is fixed so that the survey station can be seen from a distance.

The ranging rod is 2 or 3 m long and 3 cm in diameter. Is equal to. The ranging rod is made from a material like wood or bamboo.

A shoe is placed at the bottom end of the ranging rods to easily fix it to the ground. The height of the shoe is 15 cm. Length.

20 cm white and black stripes are drawn on the ranging rod to make it visible from a distance. In addition, the flag is hoisted on the top of the ranging rod for visibility.

Offset Rods

Offset rods are used to rotate the survey line or take offset at right angles. It is 3 m long and 3 cm in diameter. It has a groove or hooks at one end. With the help of which the chain can be pulled.

Offset rods have two rectangular holes. These holes are kept at eye height. Used to take offset at right angles.

Plumb Bob

The plumb bob is used in plumbing in general works like ranging rods and arrows, etc.

Hammer

Hemmers are used in general work, such as fixing wooden pegs to the ground.

Types of Chains Used in Surveying

- Metric chains.

- Steel band or band chain.

- Gunter’s chain or surveyor’s chain.

- Engineer’s chain.

- Revenue chain.

1. Metric Chains

Metric chain is used more after the implementation of the metric system in India. Metric chains are commonly used in the market in lengths of 5, 10, 20, and 30 meters. In chains of 5m and 10m, the tally is fixed at the end of each meter.

Chains of 20 and 30 m in length have a small brass ring on each meter and tally at the end of every 5 m.

2. Steel Band or Band Chain

The steel band consists of a blue steel strip of equal width of 12 to 16 mm and a thickness of 0.3 to 0.6 mm. Metric steel bands of 20 or 30 meters are mostly used. Its continuous use causes changes in the length of the chain.

3. Gunter’s Chain

The gunter chain is also known as the surveyor’s chain. Gunter’s chain is 66 feet long, and this chain is made up of 100 links.

4. Engineer’s Chain

The length of the engineering chain is 100 feet. Each 1-foot link is attached to this chain. Thus engineer chain is made up of 100 links.

5. Revenue Chain

The standard length of this type of chain is 33 feet. The number of links in this chain is 16, the distance between each link is 2 1/16 feet. This chain is commonly used in cadastral surveys.

Technical Terms of Chain Surveying

1. Base Line

In a chain survey, the long line between the survey area is taken as the baseline. The baseline is selected in such a way that it passes through an open area and has a flat surface.

The baseline should be measured twice as the accuracy of surveying depends on the baseline.

2. Tie line

The line connecting the tie stations and the checking line is called the tie line. Such a line that stays away from the main details. The tie line is used to avoid interior details and long offsets.

3. Check Line

The line joining the point of a triangle for fixed points at its base is known as a checking line.

It is used to check the accuracy of the triangle and sometimes to find the inner details.

4. Main Survey Stations

Places showing the vertices of the survey triangle on the field are called main survey locations. The following points should be kept in mind while selecting this survey location.

- Survey locations should be determined from one station to another.

- The line connecting the survey locations should be formed keeping in mind that the triangle is well-formed.

- In a chain survey, fewer lines should be decided as survey lines. surveys line should be determined as it passes through a flat surface and an open area.

- In a chain survey, a baseline should be determined for the survey. The baseline should intersect each other in an x shape.

- There should be a checking line for each triangle formed for the chain survey.

- The main survey line should be in the boundary area of the property.

5. Tie Station

The location of the survey points at both ends of the coincidence line on the main lines is called the coincidence location.

Coincidence locations are marked by a 6 mm triangle above the map.

6. Offset

lateral measurements are taken to the left and right of the survey line to determine the location of the survey above.

The lateral measurement taken over the survey line in this way is called offset. There are two types of offset.

- perpendicular offset

- oblique offset

7. Range Tie and Check Tie

When the details of a building, building, fence, etc. are to be displayed on the most diagonal corners, marking is done by range tie and check tie, as shown in the figure.

8. Location Sketches of Stations

The work of chain surveying in a large area cannot be completed by measurement in a day. Because of this, the location of each survey is prepared by Sketch to rearrange the location of the survey at any time. This field corresponds to the marking of the north direction on the sketch.

Procedure for Chain Surveying

1. Reconnaissance survey

An initial inspection of the field should be done before starting a detailed survey of the field. Which is a useful and necessary thing for the survey.

Preliminary inspections are carried out for the purpose of fixing survey stations and planning for a network of chain lines. The inspection of the survey must ensure that the survey stations should not have difficulty in ranging from the chain.

2. Marking Stations

Survey stations should be marked in such a way that they are visible to each other.The wooden pegs are then fixed to the ground.

3. Reference sketches

A brief description of each survey station should be recorded in the field book.

At least three criteria should be displayed in the sketch. The location is determined using a reference such as a gate, pillar, light post, corner of a building, etc.

4. Running survey lines

The survey lines are detailed below. Stations are built using the baseline. The chain actually puts one end of the chain on the starting station.

The lateral measurements by the chains are noted in the field book. The process of chain and offset is repeated until the end of this baseline The construction conditions are determined locations with respect to the survey line.

Advantages of Chains in Surveying

- Chain survey is a simple and common method used in surveys.

- The tools used to do chain surveying are easy to use.

- The tools used in chain surveying can be easily changed as needed. For example, measuring rods and measuring tape can be replaced.

- Chain surveys can be easily done by a few men to survey. A chain survey team usually needs three people. It has a booker, a leader, and a follower.

- This method has very little calculation. So this method of survey is simple.

Disadvantages of Chains in Surveying

- Chain surveys cannot be used in built-up areas and large areas.

- Simple chain surveys have a lot of potential for errors, which may be due to different chain positions. Failure to pull the chain connection properly results in inaccurate data. In addition, chain surveying can lead to errors in chain reading.

- Chain surveying fields are time-consuming.

- It is difficult to do chain surveying in areas with steep slopes or water bodies. Chain surveying is usually done in dry areas. When surveying areas that are very wet, it becomes complicated.

- Chain surveys become a more complex and tedious method if there are obstacles over the survey area.

Like this post? Share it with your friends!

Suggested Read –

- 5 Best Sealer for Granite Countertops

- 10 Best Gutter Alternatives

- 5 Best Battery for Sump Pump Backup 2023

- 6 Best Surface Cleaner for Pressure Washer

- 8 Best Alternatives to Glass Shower Doors

- What Size Staples for Insulation?

- What Is the Best Brand of Carpet to Buy?

- What are the Alternatives to Bifold Doors?

- 7 Best Alternatives To PVC Pipes

Skip to content

Skip to content